Commercial HVAC Preventive Maintenance Tips to Save Money

- shawncovenantaire

- Jul 21, 2025

- 17 min read

So, what exactly is commercial HVAC preventive maintenance? At its core, it's a proactive plan of regularly scheduled inspections, cleanings, and tune-ups. The whole point is to prevent expensive breakdowns and keep your system running at peak efficiency.

Think of it as a routine physical for your building's most critical system. It’s the best way to ensure everything runs smoothly all year long.

Why HVAC Preventive Maintenance Is Essential

You wouldn't try to run a marathon without training, right? Your body would almost certainly give out. A commercial HVAC system isn't all that different. When it’s forced to run day in and day out under constant stress without any professional care, it's not a question of if it will fail, but when.

This is where preventive maintenance comes in. It’s a strategic, scheduled approach that flips facility management from a reactive state (scrambling for emergency repairs) to a proactive one (planned upkeep). Instead of waiting for a total system failure during a sweltering summer heatwave or a bitter cold snap, this strategy focuses on catching and fixing small issues before they snowball.

Protecting Your Most Valuable Assets

For any commercial building, the HVAC system is one of the biggest and most expensive assets you own. Letting it fall into disrepair is like leaving a six-figure investment out in the rain to rust. Without the right care, parts wear out faster, efficiency plummets, and the system's entire lifespan gets cut short.

Regular maintenance tackles this head-on with critical tasks that keep the system in prime condition. This isn't just about keeping people comfortable; it's about protecting your financial investment and ensuring your business can keep its doors open. A full system replacement can easily run into the tens of thousands of dollars, an expense that proper maintenance can push off for years.

If you want to dig deeper into this, you can check out [a guide to commercial HVAC preventative maintenance](https://www.covenantairesolutions.com/post/a-guide-to-commercial-hvac-preventative-maintenance) that covers these ideas in more detail.

The Core Goals of Proactive Care

The true purpose of a maintenance program goes far beyond just fixing what’s broken. It's built to deliver specific, measurable results that benefit your entire operation.

A well-maintained system isn't just about comfort; it's about creating a safe, productive, and cost-effective environment. Proactive care ensures your equipment is serviceable and clean, directly extending its life, maintaining air quality, and delivering significant energy savings.

This forward-thinking approach delivers a whole host of benefits, impacting everything from your utility bills to your team's well-being.

To get a clearer picture, let's break down the primary objectives of a solid maintenance plan.

Core Goals of HVAC Preventive Maintenance

Objective | Description | Key Benefit |

|---|---|---|

Boost Energy Efficiency | Ensuring components like coils and filters are clean and all parts are calibrated for optimal function. | The system uses far less energy to heat and cool, significantly lowering utility bills. |

Extend Equipment Lifespan | Reducing wear and tear on motors, belts, and other moving parts through regular lubrication and adjustments. | The entire system lasts closer to its full intended service life, delaying major replacement costs. |

Improve Indoor Air Quality | Actively removing dust, debris, allergens, and potential mold growth from within the HVAC system. | The air that employees and customers breathe is cleaner and healthier. |

Enhance Reliability & Comfort | Fine-tuning the system to provide consistent temperatures and prevent unexpected shutdowns. | Eliminates hot/cold spots and drastically reduces the risk of business-disrupting breakdowns. |

Ultimately, a proactive stance delivers a range of benefits that impact everything from your bottom line to employee productivity. For instance, just keeping the condenser coils clean on a 60-ton cooling system can save over 35,000 kWh in a mere three months. That’s a serious return on investment.

The Financial Case for Proactive Maintenance

It's easy to see preventive maintenance as just another line item on the budget. But in reality, it's a high-return investment. Shifting your mindset from expense to investment is the key to understanding the powerful financial case for proactive commercial HVAC care.

The alternative, the “run-to-failure” approach, might seem cheaper in the short term, but it almost always leads to catastrophic costs. Think of your HVAC system like a critical piece of machinery for your business. You wouldn't skip oil changes on your company's delivery truck to save a few bucks today, only to have the engine seize up on the highway tomorrow. That single breakdown halts operations and brings a mountain of unexpected bills.

Proactive maintenance is that scheduled, affordable tune-up that keeps your business running without those expensive, show-stopping interruptions.

Slashing Direct Operational Costs

The most immediate financial win you’ll see from a solid maintenance program is a drop in your direct expenses. These are the tangible costs you can track on your monthly and annual statements. Simply put, a system that is regularly cleaned, calibrated, and inspected runs better and costs less to operate.

This improvement shows up in a few key areas:

Lower Energy Bills: A well-maintained HVAC unit is an efficient one. When coils are clean and filters are clear, your system doesn't have to fight to heat or cool your space. This directly translates to lower utility bills every single month.

Fewer Emergency Repairs: Planned maintenance catches the small stuff, a frayed belt, a minor leak, before it spirals into a full-blown system failure. This drastically cuts down on the need for expensive, after-hours emergency service calls, which always come with premium labor rates.

The High Price of Reactive Maintenance

If you're not planning for upkeep, you're effectively choosing the most expensive management strategy possible. The numbers don't lie. Industry analysis consistently shows that commercial hvac preventive maintenance can generate cost savings of 8-12% over a reactive, run-to-failure approach.

Even more telling, advanced, reliability-focused strategies have shown savings as high as 30-40%. Despite this, a surprising 52% of facilities still gamble with a run-to-failure model, leading to much higher long-term expenses and a shorter lifespan for their equipment.

Waiting for a system to break isn't a strategy; it's a gamble against odds that are heavily stacked against you. The cost of one major component failure, like a compressor, can easily surpass the cost of several years of preventive maintenance visits.

This reactive cycle throws your budget into constant uncertainty, making any kind of real financial planning next to impossible.

Deferring Major Capital Expenditures

One of the biggest financial wins of a maintenance plan is pushing back the massive cost of a full system replacement. A commercial HVAC system is a huge capital investment, and having to replace it prematurely can derail your budget for years.

Regular maintenance is the single most effective way to protect that investment. By reducing daily wear and tear and catching problems early, you can add years to your system’s operational life. This allows you to defer that major replacement expense, freeing up capital for other business growth initiatives. When that replacement day does eventually come, it's smart to know your options. You can learn more about [HVAC financing options and easy ways to save on your system](https://www.covenantairesolutions.com/post/hvac-financing-options-easy-ways-to-save-on-your-system) in our detailed guide.

Unlocking Powerful Indirect Returns

The financial benefits don't stop with direct savings. A reliable and efficient HVAC system creates a ripple effect of positive returns that support your entire business.

Improved Productivity: A comfortable environment with consistent temperatures and good air quality helps your team stay focused and productive.

Higher Tenant Retention: For commercial landlords, a dependable HVAC system is a major factor in tenant satisfaction. Happy tenants are far more likely to renew their leases, which cuts down on costly turnover.

Preserved Asset Value: A well-maintained HVAC system is a valuable feature that contributes to the overall worth of your commercial property, making it a more attractive asset.

Your Essential HVAC Maintenance Checklist

A proactive approach to commercial HVAC preventive maintenance needs more than just good intentions; it demands a structured plan. A detailed checklist is your most powerful tool here, turning abstract goals into concrete, actionable tasks. By organizing these jobs seasonally, you can make sure your system is perfectly prepped for the stress of both peak cooling and heating seasons.

This isn't just about ticking boxes. It's about understanding the "why" behind each action. For instance, cleaning condenser coils isn't just a chore; it’s a critical step that guarantees efficient heat transfer, which directly lowers your energy consumption. Likewise, verifying refrigerant levels prevents the catastrophic failure of your system's most expensive component: the compressor.

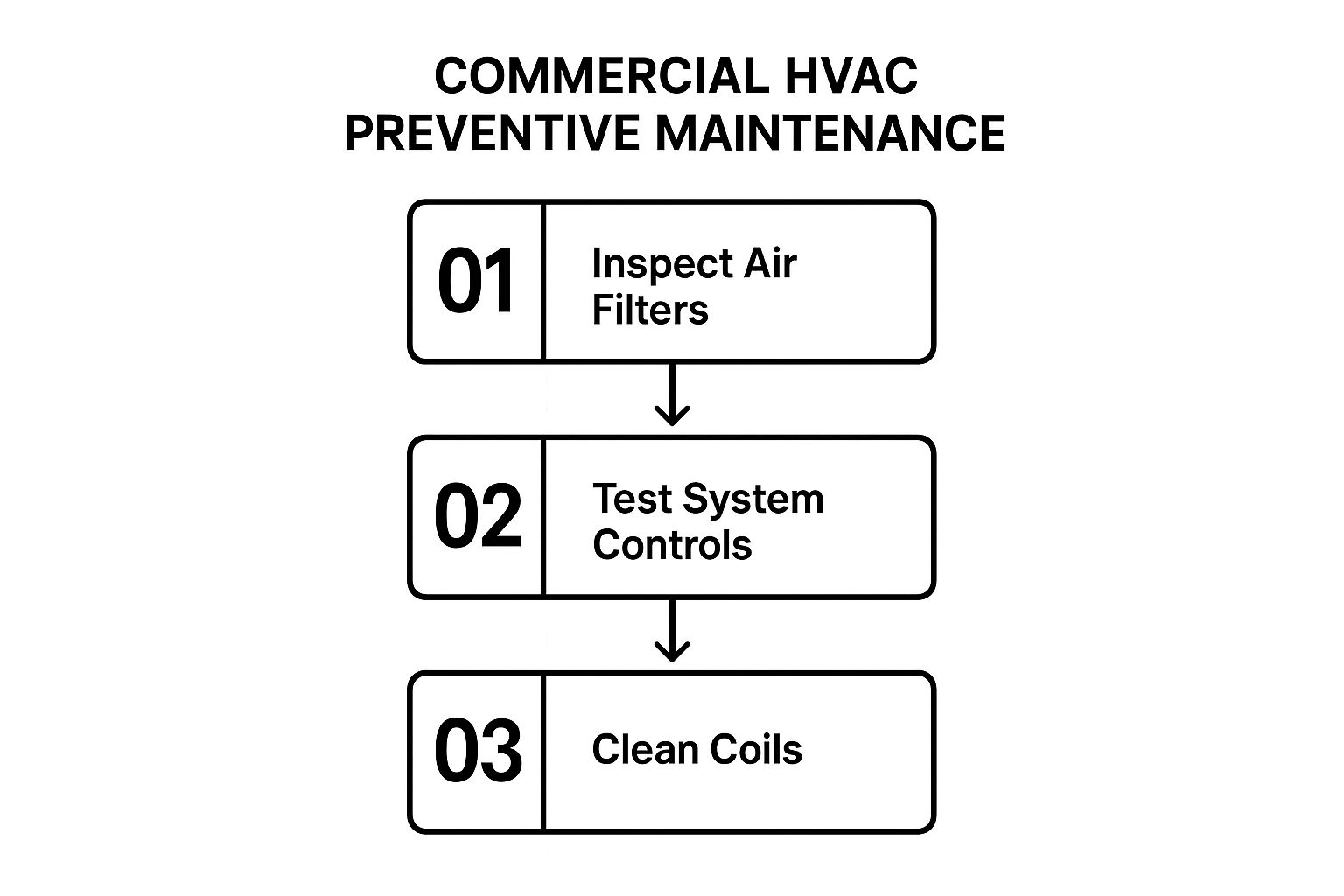

The following infographic breaks down the core maintenance sequence into three fundamental steps.

This visual guide shows how a consistent maintenance routine starts with the basics, like air filters, moves to system controls, and then addresses major components like coils.

To give you a clearer picture, here’s a look at how tasks break down by season. This helps ensure your system is always ready for what the weather throws at it.

Sample Seasonal HVAC Maintenance Tasks

Task | Spring/Summer Focus (Cooling) | Fall/Winter Focus (Heating) |

|---|---|---|

Coil Inspection | Clean outdoor condenser coils to ensure efficient heat rejection. | Inspect indoor evaporator coils for dirt and proper drainage. |

Component Check | Inspect and lubricate condenser fan motor and blades. | Inspect and clean burner assembly and ignition system. |

Safety & Controls | Verify thermostat calibration and cooling cycle operation. | Test all safety controls, including limit switches and flame sensors. |

Drainage Systems | Clean condensate drain lines to prevent water backup and damage. | Check and clear flue and vent pipes for blockages. |

System Vitals | Check refrigerant levels and pressures for optimal performance. | Check and adjust gas pressure for safe, efficient operation. |

This table is a great starting point, but let's dive a little deeper into what each season's prep work really involves.

Spring and Summer Cooling Preparations

As warmer weather approaches, the focus shifts entirely to your air conditioning system. These tasks are designed to guarantee your equipment can handle the intense demands of summer heat without failing. This is all about ensuring a cool and comfortable environment for employees and customers.

Key cooling season tasks include:

Inspecting and Cleaning Condenser Coils: Outdoor condenser coils are what push heat out of your building. When they get caked in dirt and debris, they can't do this job effectively, forcing the system to work much harder and use more energy.

Checking Refrigerant Levels and Pressures: Incorrect refrigerant levels can cause serious damage. Too little, and the system struggles to cool. Too much, and you risk destroying the compressor.

Cleaning Condensate Drains: Air conditioning naturally produces condensation. A clogged drain line can lead to water backing up, causing significant water damage and potential mold growth inside your facility.

Inspecting and Tightening Electrical Connections: Loose or corroded electrical connections are a serious fire hazard and can lead to component failure. A technician will make sure all wiring is secure and safe.

Lubricating Motors and Bearings: Proper lubrication reduces friction on all moving parts. This simple step minimizes wear and tear and prevents premature motor burnout.

Fall and Winter Heating Preparations

Before the first cold snap hits, your maintenance plan has to pivot to prepare the heating components of your HVAC system. A failure here can lead to uncomfortable, or even unsafe, conditions during the coldest months of the year.

A common mistake is neglecting the heating system just because it's not used as frequently in milder climates. Even moderate use requires a professional tune-up to ensure safety, reliability, and efficiency when it's needed most.

Heating season prep involves a different but equally important set of checks.

Key heating season tasks include:

Inspecting the Heat Exchanger: For any gas furnace, the heat exchanger is a critical safety component. A cracked heat exchanger can leak deadly carbon monoxide into your building, making this inspection absolutely non-negotiable.

Testing Ignition and Burner Components: A technician will clean and test the furnace's ignition system and burners. This ensures they operate safely and efficiently, preventing a no-heat emergency on the coldest day of the year.

Checking All Safety Controls: This includes testing limit switches and other safety mechanisms designed to shut the system down if it overheats or malfunctions.

Verifying Gas Pressure and Connections: Proper gas pressure is essential for both effective heating and safe operation. Technicians will check for any leaks in the gas line.

Year-Round Maintenance Essentials

Some tasks are so fundamental to system health that they have to be performed consistently throughout the year, regardless of the season. These ongoing duties form the backbone of any successful commercial HVAC preventive maintenance program.

The most critical among them is managing your air filters. Clogged filters absolutely destroy efficiency by restricting airflow, and they seriously degrade your indoor air quality. For a more detailed breakdown, you can explore our [HVAC preventative maintenance checklist with 7 tips for 2025](https://www.covenantairesolutions.com/post/hvac-preventative-maintenance-checklist-7-tips-for-2025). This resource provides extra guidance on keeping your system in top shape all year.

The way we handle commercial HVAC preventive maintenance is changing, and fast. Gone are the days of just circling a date on the calendar and hoping for the best. Technology is pushing us past those rigid, time-based schedules toward a much smarter, more effective approach: servicing equipment based on its actual condition.

This shift isn't just happening for its own sake. It's being driven by a huge focus on sustainability and energy efficiency, backed by new regulations and corporate responsibility goals. As businesses hunt for ways to shrink their environmental footprint and cut operating costs, HVAC systems are right at the top of the list for improvements.

The Rise of Intelligent Maintenance

The market for commercial HVAC preventive maintenance is already massive, but it's set to grow even more. Starting from a base of around $10 billion in 2025, it’s projected to expand at a compound annual rate of about 5% through 2033. This growth is directly tied to new commercial construction and the rapid adoption of smart tech that makes predictive upkeep possible.

This move toward intelligent maintenance is all about listening to what your equipment is telling you. Think of it like a heart rate monitor for your building’s climate system. Instead of just a check-up once a year, its health is tracked constantly, feeding you a steady stream of priceless data.

The core idea is simple but incredibly powerful: fix something based on its real-time condition, not just because a certain amount of time has passed. This data-first strategy avoids needless service calls while catching real problems before they turn into catastrophic failures.

This smarter approach hinges on a few key technologies that work together, creating a maintenance ecosystem that's far more responsive and efficient than anything we've had before.

Key Technologies Driving the Change

This move to predictive and condition-based maintenance isn't just a concept; it's a reality powered by interconnected systems. These tools gather, analyze, and act on performance data in real-time, giving facility managers a level of control that was once unimaginable.

Three technologies are really at the heart of this transformation:

Internet of Things (IoT) Sensors: These small but mighty sensors are the eyes and ears of a modern HVAC system. You can place them on motors, compressors, and air handlers to constantly monitor things like temperature, vibration, and energy use. An unusual vibration pattern, for instance, can warn you that a bearing is about to fail, long before it actually does.

Building Automation Systems (BAS): A BAS is the central nervous system for your entire facility. It pulls in all the data from IoT sensors and other building systems, organizing it onto a single, easy-to-manage platform. This allows for automated adjustments, like a system that can automatically dial back airflow to an empty office wing to save energy without anyone lifting a finger.

Predictive Analytics: This is where all that data becomes truly powerful. Sophisticated software uses algorithms to sift through the flood of information from your sensors and BAS. It spots patterns and trends that would be impossible for a human to see, accurately forecasting when a specific component will likely need attention.

Working in concert, these technologies create a system that doesn't just react to problems; it sees them coming. This gives us a clear look into the future of facility management, where decisions are driven by hard data, not guesswork. Of course, moving from a basic checklist to a dynamic system like this requires a solid understanding of scheduling, which you can read all about in our guide covering [your essential HVAC maintenance schedule](https://www.covenantairesolutions.com/post/your-essential-hvac-maintenance-schedule).

Customizing Maintenance for Your Climate and Building

When it comes to commercial HVAC preventive maintenance, a generic, one-size-fits-all checklist is a recipe for failure. Your building isn't a cookie-cutter box, and where it's located has a huge impact on how its climate systems work, and what they need to stay healthy. A truly effective strategy has to be built around your specific environment.

Think about it: you wouldn't treat a system baking in a desert the same as one enduring a humid coast. Each climate throws unique challenges at your equipment. A standard checklist will inevitably miss these critical regional factors, leading straight to poor performance, premature wear, and wasted energy.

Adapting to Regional Climate Demands

The local climate is the single biggest influence on your maintenance plan. The nonstop fight against heat, cold, humidity, or dryness determines which parts of your HVAC system are under the most strain. By tailoring your plan, you focus your resources where they’ll make the biggest difference.

For instance, a building in a hot, humid coastal area like Florida is in a constant battle with moisture and salt-laced air. This calls for a very specific maintenance focus.

Focus on Dehumidification: The system is working overtime just to pull moisture from the air. This means frequent checks on condensate drains and dehumidification cycles are a must.

Prevent Corrosion: Salt in the air is incredibly corrosive and eats away at outdoor units, especially condenser coils. Technicians have to be on the lookout for rust and treat it before it causes component failure.

Combat Mold Growth: High humidity is the perfect breeding ground for mold and mildew inside ductwork and on evaporator coils. Regular, thorough cleaning becomes a top priority for protecting air quality.

A maintenance plan that works perfectly for a building in dry, arid Arizona would be completely inadequate for a facility in a damp, coastal region. Customization isn't just a good idea; it's essential for system longevity and efficiency.

In sharp contrast, a building in a cold, dry climate like Colorado faces a completely different set of hurdles. Its commercial hvac preventive maintenance plan needs to focus on the opposite threats.

Prioritize Heating Performance: The furnace or boiler is the undisputed workhorse. It demands rigorous inspection of its burners, heat exchangers, and ignition systems well before winter arrives.

Manage Humidification: Bone-dry winter air isn't just uncomfortable; it can damage building materials. Maintenance must ensure humidifiers are working correctly to add essential moisture back into the air.

Protect from Freeze-ups: Any outdoor pipes or components are at risk of freezing solid. Technicians need to meticulously check insulation and heat tracing to prevent catastrophic (and expensive) damage.

Navigating Global and Local Regulations

Beyond just the weather, your maintenance strategy is also shaped by government regulations and energy codes, which can vary dramatically from one place to the next. Regional dynamics, influenced by local rules and technological adoption, play a major part in these practices. For example, North America's strict energy codes and older infrastructure drive demand for advanced preventive services. Meanwhile, Europe navigates a complex web of regulations, and the Asia-Pacific region is heavily focused on smart building integration. You can find a deeper analysis of these global maintenance trends and regional factors to see how different markets are evolving.

What this means for you is that a maintenance provider has to adapt their methods to meet these local requirements. The rules for handling and disposing of refrigerants in North America, for example, might be very different from those in Europe. A good local partner understands these nuances. They ensure your maintenance plan not only keeps your system running but also keeps you compliant, efficient, and ready for whatever your unique environment throws at you.

How to Choose the Right HVAC Maintenance Partner

Picking a partner for your commercial HVAC preventive maintenance is one of the most important calls a facility manager can make. This isn't just about finding someone to fix what’s broken; it’s about starting a long-term relationship with a company you trust to protect a major financial asset. A great partner is a true guardian of your system.

The right provider doesn't just show up and check boxes. They offer strategic advice to boost efficiency and head off problems before they start. Think of it less like hiring a handyman and more like finding a specialist physician for your building's most critical system. Your goal is to find a team that’s qualified, reliable, and transparent.

Verifying Credentials and Experience

Before you even think about a contract, your first step is to vet a potential partner’s basic qualifications. These are the non-negotiables that prove they’re a legitimate, capable business. Cutting corners here can expose you to huge liability and shoddy work.

Start with these essential checkpoints:

Licensing and Insurance: The company absolutely must be fully licensed to work in your state and carry comprehensive insurance, including liability and workers' compensation. Ask for the paperwork and verify it. This is what protects you if an accident happens on your property.

Industry Certifications: Look for technicians who hold respected certifications like NATE (North American Technician Excellence). NATE certification is the gold standard in our industry, proving a technician has passed rigorous, real-world tests of their knowledge.

Proven Experience: Don't be shy; ask for specific examples of their work on commercial systems just like yours, whether you have rooftop units, chillers, or complex multi-zone systems. Experience with residential units doesn't automatically translate to commercial expertise.

Asking the Right Questions

Once you have a shortlist of qualified candidates, it’s time to dig deeper. How a company answers these questions will tell you a lot about their day-to-day operations and their real commitment to service. Their responses will paint a clear picture of what it’s like to work with them, especially when something goes wrong.

A truly professional HVAC partner will welcome detailed questions and give you clear, direct answers. If you get vague responses or they seem hesitant to share specifics about their protocols, consider it a major red flag.

Make sure you ask potential vendors about the following:

Emergency Response Protocols: What’s your guaranteed response time for an emergency call? Do you offer 24/7 service, and what are the rates for after-hours work?

Service Contract Transparency: Can I see a sample contract? What, exactly, is included in your commercial HVAC preventive maintenance plan, and what’s considered an extra charge?

Reporting and Communication: What kind of service reports will I get after each visit? How do you document problems you find and recommend repairs?

Technician Assignment: Will we have a dedicated technician or team assigned to our account? Having the same person work on your equipment builds familiarity with its specific history and quirks.

Finally, always get detailed, written proposals from each finalist and ask for local business references. Speaking with other facility managers they currently serve is one of the best ways to confirm you’re making a wise choice to protect your investment.

Frequently Asked Questions

Even after going through a comprehensive guide, it's natural to have a few more specific questions pop up. Facility managers and building owners often have the same lingering thoughts about commercial HVAC maintenance, so let's tackle them head-on.

Think of this as a quick-reference section to clear up any final details. It’s designed to give you the confidence to make smart, informed decisions about your system's care.

How Often Should Commercial HVAC Maintenance Be Performed?

The honest answer is: it depends. The right schedule is always tied to your system's age, how hard it runs, and the environment it's in. That said, the universal industry benchmark is a professional tune-up at least twice per year.

Typically, this means one visit in the spring to get the cooling system ready for summer and another in the fall to prep the heating system for winter. For buildings with intense demands, think data centers, hospitals, or busy manufacturing plants, quarterly service is often a much better fit.

While the deep technical work is best left to pros twice a year, some basic tasks are an ongoing responsibility. Simple but vital jobs, like swapping out air filters, need to be done far more often, usually every 1 to 3 months, depending on how clean you need your building's air to be.

This two-pronged approach, combining professional tune-ups with routine in-house checks, is the key to keeping everything running smoothly.

What Is the Average Cost of a Commercial HVAC Maintenance Contract?

Pinning down an "average" cost for a commercial HVAC maintenance contract is tricky because the price tag swings wildly based on a few key factors. The final cost really comes down to the size, age, and complexity of your equipment, plus the level of service you choose.

For instance, a basic agreement for a small retail shop might only be a few hundred dollars per visit. On the other hand, a comprehensive contract for a large office building with a dozen rooftop units could easily run into several thousand dollars a year. It’s absolutely essential to get detailed quotes that spell out exactly what’s included: labor, parts, and especially the rates for emergency service calls.

Can In-House Staff Handle HVAC Preventive Maintenance?

Yes, absolutely! Not only can your in-house team handle some tasks, they should. It's often the most practical and efficient way to manage the day-to-day upkeep of your system.

Your own staff is perfectly positioned to take care of the high-frequency jobs, like:

Changing air filters every month or quarter.

Wiping down vents, grilles, and registers to keep them clear of dust and debris.

Doing quick visual walk-throughs to spot obvious problems like water leaks or weird noises.

However, the more technical work demands specialized tools, strict safety knowledge, and professional certification. Things like checking refrigerant pressures, inspecting high-voltage electrical connections, and servicing motors should always be handled by a certified HVAC contractor. The best strategy is a partnership: your team manages the basics, and you bring in a pro for the heavy lifting.

Protecting your commercial property means having a reliable, expert partner in your corner. Covenant Aire Solutions offers comprehensive preventive maintenance plans built to keep your systems running at peak efficiency, extend their lifespan, and give you peace of mind with transparent pricing and exceptional service. Ensure your business stays comfortable and productive year-round by visitingcovenantairesolutions.com to schedule your consultation today.