Understanding Your Furnace's Secondary Heat Exchanger

- shawncovenantaire

- 11 hours ago

- 13 min read

If you have a high-efficiency furnace, you have a secondary heat exchanger. This is the key component that pushes your furnace’s efficiency into the 90% and higher range. Think of it as a recycling center for heat, grabbing extra energy from the exhaust that would otherwise just float out your vent pipe.

The result? You wring out more warmth from the same amount of fuel, which is great news for your utility bills.

Your Furnace’s Efficiency Powerhouse Explained

Let's use an analogy. Imagine your furnace's primary heat exchanger is like the first big blast of power from a car engine. It’s where the main combustion happens, creating a ton of heat. In an older, standard-efficiency furnace, the hot exhaust from this first step is immediately sent outside, wasting a lot of potential warmth along with it.

This is where the secondary heat exchanger completely changes the game.

It gives that hot exhaust a second chance to heat your home. Before those fumes escape, they’re redirected through this second component. Here, another heat transfer takes place, pulling out even more thermal energy from the exhaust and sending it into your home’s air.

The Power of Condensation

What makes this second stage so incredibly effective is condensation. As those hot exhaust gases cool down to about 130°F, the water vapor inside them turns into liquid. This is a big deal, because that change from gas to liquid releases a powerful burst of what’s called latent heat.

That captured heat is then used to warm your home. It’s also why high-efficiency furnaces produce a small trickle of acidic water, called condensate, that has to be drained away. That condensate is physical proof that your furnace is squeezing every last bit of energy out of the fuel it’s burning.

The secondary heat exchanger is the main reason modern furnaces can achieve Annual Fuel Utilization Efficiency (AFUE) ratings of 90% or higher. A standard furnace, in contrast, might only hit an 80% AFUE. That means 20 cents of every dollar you spend on fuel is lost straight up the chimney.

Why This Matters for Tucson Homeowners

For those of us here in Tucson, maximizing every bit of heating efficiency is the best way to keep those winter utility bills from creeping up. A furnace equipped with a secondary heat exchanger ensures you’re getting the most comfort for your money by capturing and reusing heat that would otherwise be wasted. For those interested in the technical side, understanding your furnace's energy use involves knowing how to convert cubic meters to kilowatts.

This technology doesn’t just put money back in your pocket; it also shrinks your home's environmental footprint. You can learn more about how all these parts work together in our guide to HVAC system efficiency. At the end of the day, this powerhouse component is working quietly behind the scenes to deliver reliable, cost-effective warmth when you need it most.

How Primary and Secondary Heat Exchangers Work Together

To really get a handle on how a high-efficiency furnace squeezes so much performance out of every drop of fuel, it helps to see its two heat exchangers as a tag team. The primary heat exchanger is the powerhouse of the operation. It’s the first in line, taking the full, intense blast of heat directly from the furnace burners. Its job is to handle that initial, powerful transfer of warmth into your home’s air.

But even after that first step, there’s a ton of heat left over in the exhaust gases. In older, less efficient furnaces, all that valuable energy was just vented straight outside: a complete waste. This is exactly where the secondary heat exchanger comes in, acting as a specialist to capture and recycle that leftover energy.

A Tale of Two Materials

The primary heat exchanger is built tough, usually from heavy-duty materials like aluminized or stainless steel, because it has to stand up to extreme temperatures day in and day out.

The secondary heat exchanger, on the other hand, faces a completely different kind of challenge. As it pulls the last bits of heat from the exhaust, those gases cool down so much that acidic water vapor actually condenses back into a liquid.

To deal with this corrosive moisture, the secondary unit is almost always made from stainless steel or another corrosion-resistant alloy. This difference in materials is a key distinction between the two and is absolutely vital for the long life of a high-efficiency system.

For a deeper dive into the basic functions of these parts, check out our guide on what a furnace heat exchanger is and why it matters.

To help you see how these two parts differ, we've put together a quick comparison.

Primary vs Secondary Heat Exchanger At a Glance

Feature | Primary Heat Exchanger | Secondary Heat Exchanger |

|---|---|---|

Main Job | Initial, high-temperature heat transfer from burners. | Captures leftover heat from exhaust gases. |

Typical Material | Aluminized steel or standard stainless steel. | High-grade, corrosion-resistant stainless steel. |

Operating Temp | Very high. | Much lower; deals with condensation. |

Key Challenge | Withstanding intense, direct heat. | Resisting corrosion from acidic condensation. |

This table highlights the specialized roles each component plays. While the primary unit handles the raw power, the secondary unit's sophisticated design is what pushes the furnace into high-efficiency territory.

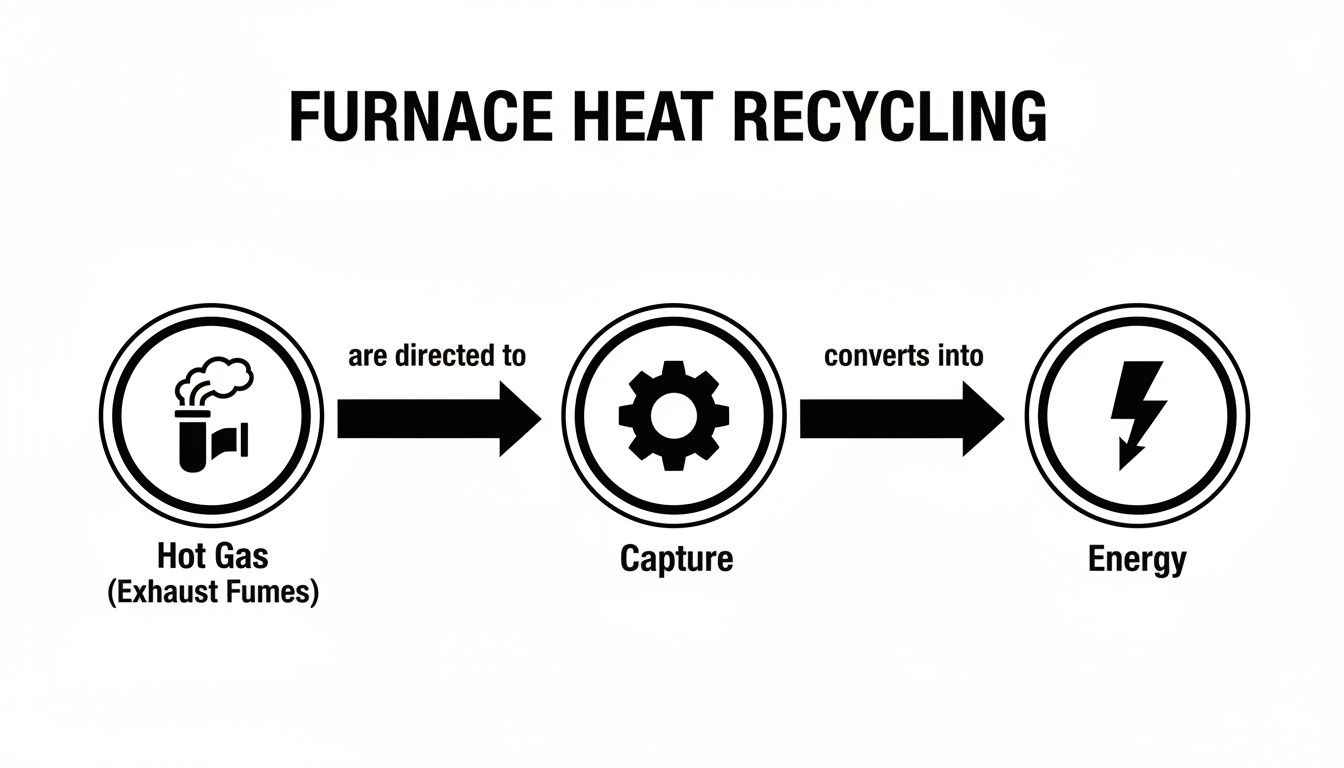

This diagram helps visualize how the secondary heat exchanger recycles that hot exhaust gas into energy your furnace can actually use.

As you can see, what was once just wasted exhaust is now captured and put back to work, giving your furnace’s output a serious boost.

The Teamwork That Drives Efficiency

The whole process works in a simple, one-two punch. First, the primary exchanger does the heavy lifting with the initial high-temp transfer. Then, the exhaust moves on to the secondary exchanger. This is where the magic really happens: it wrings out nearly every last bit of energy through condensation before the now-cool gases are vented outside.

This two-stage system is precisely why modern furnaces can achieve Annual Fuel Utilization Efficiency (AFUE) ratings of 90% or more. It means that for every dollar you spend on fuel, at least 90 cents goes directly into heating your Tucson home.

It's no surprise that homeowners are increasingly looking for this level of efficiency. For anyone in the Tucson area looking to upgrade their system, a furnace with a secondary heat exchanger is a game-changer. It delivers better heat transfer, cuts down on energy waste, and ultimately leads to lower utility bills.

Recognizing the Warning Signs of a Failing Exchanger

Your high-efficiency furnace is a pretty sophisticated piece of equipment, but thankfully, it usually gives you some clear hints when something’s not right. While the secondary heat exchanger is built to last, it’s not invincible. Catching the early warning signs can be the difference between a simple fix and a full-blown furnace failure in the middle of a cold Tucson night.

Acting fast on these symptoms is your best bet to head off more expensive, complicated damage.

One of the most common and hard-to-miss signs is water pooling around the base of your furnace. Remember how the secondary heat exchanger's job is to create condensation? Well, that water needs to go somewhere, and it has a dedicated drain line to do just that. If you spot a puddle, it’s a big red flag that the drain is clogged or, worse, the exchanger itself has cracked.

Sounds and Smells That Signal Trouble

Beyond what you can see, your ears and nose are surprisingly good diagnostic tools. A healthy furnace has a predictable, steady hum. A failing secondary heat exchanger, on the other hand, can introduce some new, unsettling sounds to the mix.

Keep an ear out for these specific noises when your heat kicks on:

Popping or Rattling: This often means the metal inside the exchanger is expanding and contracting under stress. It's usually caused by blockages or an internal failure.

Loud Banging: A sudden bang right when the furnace starts could point to delayed ignition. Over time, that kind of stress can really take a toll on the heat exchanger.

Unusual Odors: A smell like burning plastic or hot metal can mean components are overheating. If you get a musty or sharp, acrid smell, it could be a problem with the condensate drainage system.

These are just a handful of the potential symptoms. For a deeper dive, check out our post on the 8 clear signs your furnace needs repair in 2025.

Here’s a key takeaway for every Tucson homeowner: trust your senses. If your furnace looks, sounds, or smells different than it did last winter, that’s your cue to call in a professional for an inspection. Ignoring those subtle shifts can let a small problem snowball into a big one.

Performance Problems and Visual Clues

Ultimately, a failing secondary heat exchanger will start to affect how well your furnace actually heats your home, and it might even show physical signs of distress.

Be on the lookout for frequent shutdowns, where the furnace cycles on and off over and over without ever getting your home to the right temperature. This "short cycling" can be a symptom of restricted airflow caused by a clogged exchanger.

You should also look for visible rust and corrosion on the outside of the furnace cabinet or near the vent pipes. While a little surface rust isn't always a catastrophe, excessive corrosion is a bad sign. It often points to internal moisture leaks that are slowly eating away at the metal from the inside out. Spotting this early gives you the chance to call Covenant Aire Solutions for an inspection before a minor issue turns into a major failure.

The Hidden Dangers of a Damaged Heat Exchanger

Beyond performance drops and efficiency problems, a damaged secondary heat exchanger creates a serious safety hazard inside your home. This isn't just about being comfortable; it's a critical issue that affects the health and well-being of your family.

The biggest danger here is the potential for carbon monoxide (CO) to leak into your living space.

This toxic gas is a natural byproduct of your furnace's combustion process. You can't see it, and you can't smell it. A properly functioning furnace vents all of this gas safely outside your home. But when a crack or hole forms in the heat exchanger, that protective barrier is gone. Deadly exhaust fumes can then mix with the clean, warm air being pushed through your home's ductwork.

The Silent Threat of Carbon Monoxide

Because you can't see or smell it, carbon monoxide can build up to dangerous levels without anyone realizing what’s happening until it’s too late. The symptoms of CO poisoning often get mistaken for the flu, and include headaches, dizziness, nausea, and fatigue. This is exactly why having working carbon monoxide detectors on every level of your home is completely non-negotiable.

The integrity of your furnace's heat exchanger is the only thing separating the clean air your family breathes from the poisonous gases created during combustion. Even a small breach can have serious consequences, making immediate professional inspection essential if you suspect a problem.

Proper furnace maintenance isn't just about keeping your system running efficiently; it's a fundamental part of protecting your family from this silent threat. You can learn more about the risks in our article explaining what causes carbon monoxide poisoning.

A Growing Market for Safety and Efficiency

The global shift toward safer, more efficient heating solutions has driven significant growth in HVAC technology. The secondary heat exchanger market was valued at $8,862 million in 2025 and is projected to expand at a compound annual growth rate of 6.8% through 2033.

This growth reflects the increasing demand for high-efficiency systems that not only save money but also incorporate modern safety standards. You can discover more insights about these market trends on datainsightsmarket.com. At Covenant Aire Solutions, we believe that your furnace's performance and your family’s safety go hand in hand.

Repair or Replace: Making the Right Financial Decision

When one of our technicians at Covenant Aire Solutions confirms your secondary heat exchanger has failed, you’ve hit a crossroads. This isn't just about a broken part; it’s a major financial decision. Should you repair it, or is it time to replace the whole furnace?

Making the right call means looking beyond the immediate repair bill and considering the long-term value, reliability, and what makes the most sense for your home here in Tucson.

Analyzing the Core Factors

The first and most important piece of the puzzle is the age of your furnace. Most furnaces are built to last about 15 to 20 years. If your unit is already creeping up on that 15-year mark, or has already passed it, sinking a lot of money into a major repair like this is often a tough sell. Think about it: other critical parts, like the blower motor and control board, are likely on their last legs, too.

Next, you have to look at the warranty. High-efficiency furnaces often come with great warranties on the heat exchanger, sometimes even a lifetime warranty for the original owner. But here’s the catch: that coverage is usually just for the part itself. The labor to tear down the furnace and put it all back together? That’s typically on you.

Here are the key questions we walk homeowners through when they're weighing their options:

How old is the furnace? If it’s over 15 years old, replacement is almost always the smarter long-term investment.

What does the warranty cover? Is it just the part, or does it include labor? A parts-only warranty can still leave you with a hefty bill.

What’s the repair cost versus replacement? If the repair is going to cost 30-50% of what a brand-new furnace would, replacement gives you far more value and peace of mind.

What’s the furnace’s repair history? If you and your HVAC tech are on a first-name basis because of frequent breakdowns, more failures are probably just around the corner.

A new furnace isn't just a replacement; it's an upgrade. It comes with a fresh warranty on all components and brings huge gains in energy efficiency and performance. Those lower monthly utility bills can really help offset the initial investment over time.

The Long-Term Financial Picture

Choosing to repair an old furnace often feels like you’re just kicking the can down the road. You could spend a significant amount today only to have another major part give out in a year or two. Replacing the whole system essentially resets the clock, giving you a fresh start with modern, reliable technology that you won't have to worry about.

This decision also lines up with what's happening in the broader industry. The global market for heat exchangers, valued at USD 20.16 billion, is expected to climb to USD 30.79 billion by 2033. This growth shows a clear demand for more advanced, efficient heating technologies. You can read the full research about these market dynamics on imarcgroup.com.

By investing in a new, high-efficiency system, you’re not just fixing a problem, you’re aligning your home with the latest advancements in comfort and savings.

Proactive Maintenance to Prevent Costly Failures

The absolute best defense against a sudden, catastrophic secondary heat exchanger failure is consistent, proactive care. If you're waiting for warning signs to pop up, it means the damage has already started. Think of regular professional maintenance as a smart investment that catches the small, hidden issues before they spiral into expensive, emergency repairs right in the middle of a Tucson winter.

This kind of preventative approach is way more than just swapping out a filter. It’s a comprehensive tune-up designed specifically to protect the most vital, and vulnerable, parts of your high-efficiency furnace.

What a Professional Tune-Up Involves

During a maintenance visit, a certified technician from Covenant Aire Solutions runs through a specific checklist to safeguard your furnace's longevity and performance. These checks are absolutely crucial for the long-term health of your secondary heat exchanger.

A typical service will always include these key steps:

Cleaning Internal Components: We carefully clean the exchanger coils. This ensures maximum heat transfer and prevents the kind of grimy buildup that leads to overheating and stress cracks.

Inspecting and Clearing Condensate Lines: That acidic condensate has to drain freely. A technician will flush the drain line to prevent clogs, which can cause corrosive water to back up and eat away at the exchanger from the inside out.

Analyzing Combustion: Using specialized equipment, we check the fuel-to-air mixture. Getting the combustion just right is essential not only for efficiency but also for preventing harmful byproducts that degrade internal components over time.

To ensure the longevity and safety of your entire heating system, including its critical heat exchanger components, proactive care through a regular gas heater service is highly recommended. These targeted actions are what keep your system running safely and at its peak.

Investing in an annual tune-up isn't an expense; it's a strategy. It extends the life of your furnace, maintains its efficiency to keep utility bills low, and provides invaluable peace of mind knowing your system is safe.

This process ensures every part of your furnace is ready for the season ahead. You can see a detailed breakdown of what to expect in our guide, Your Ultimate 8-Point Furnace Service Checklist for 2025. Scheduling proactive maintenance is the single most effective way to prevent those costly failures and keep your family warm and safe.

Your Top Questions About Secondary Heat Exchangers Answered

Even when you have a solid grasp of how your furnace keeps you warm, it's completely normal to have questions about the more intricate parts. Over the years, we've heard just about every question from our Tucson customers regarding secondary heat exchangers. Here are the most common ones, with clear, no-nonsense answers.

Can I Clean My Secondary Heat Exchanger Myself?

We get this question a lot, and our answer is always a firm but friendly "no." We strongly advise against attempting this yourself. The secondary heat exchanger is buried deep inside your furnace cabinet, and it's constantly exposed to acidic condensate. Getting to it isn't a simple matter of removing a panel; it requires specialized tools and a deep understanding of furnace mechanics to avoid doing serious, permanent damage.

Trying to handle or clean it without the right know-how can easily crack the component or accelerate corrosion. This is one of those jobs that’s truly best left to a certified HVAC technician from Covenant Aire Solutions. During a routine maintenance visit, we can inspect and clean it safely and correctly, protecting your investment.

How Long Should a Secondary Heat Exchanger Last?

This is a great question. A secondary heat exchanger is built to be tough; it’s engineered to last the entire lifespan of the furnace itself, which is typically 15 to 20 years. But there’s a catch: its longevity is directly tied to consistent, professional maintenance.

If the furnace isn't serviced annually to inspect for corrosion and clear out the condensate drain lines, its life can be cut dramatically short. Those regular tune-ups are the single best thing you can do to make sure this critical component reaches its full service life.

The number one killer of a secondary heat exchanger is a clogged condensate drain. When that acidic water can't escape, it sits and eats away at the metal. A simple check during an annual inspection prevents this small problem from becoming a massive expense.

Is It Safe to Run a Furnace with a Faulty Exchanger?

Absolutely not. Running a furnace with a cracked or heavily corroded secondary heat exchanger is extremely dangerous. A breach can allow carbon monoxide (CO), a colorless, odorless, and highly toxic gas, to leak directly into your home's air supply.

If you have any suspicion that something is wrong, your first step should be to turn off the furnace immediately. Next, double-check that your CO detectors are working properly. Then, without any delay, call a professional for emergency HVAC service. When it comes to something this serious, your family's safety is always the top priority.

If you have more questions or you're worried about the health of your furnace’s secondary heat exchanger, don't put it off. Reach out to the trusted experts at Covenant Aire Solutions for a professional inspection and the peace of mind that comes with it. You can schedule your service online with us today.