A Guide to Commercial HVAC Preventative Maintenance

- shawncovenantaire

- Jul 11, 2025

- 16 min read

Let's be honest: treating your commercial HVAC system like just another line item on a budget is a shortsighted, and often expensive, mistake. When you’re only focused on fixing equipment after it breaks, you're playing a risky game that rarely pays off in the long run.

Think about it. An emergency shutdown during a sweltering Arizona summer. A flood of tenant complaints about bone-chilling drafts in the winter. These aren't just minor headaches; they're direct threats to your operations, productivity, and bottom line.

This is where a solid commercial HVAC preventative maintenance plan changes the entire conversation. It’s not about spending money; it's a core business strategy that protects your assets, keeps your building's occupants comfortable and productive, and ensures your operations run like clockwork.

Why Proactive HVAC Maintenance Is a Business Imperative

The reactive, "fix-it-when-it-breaks" approach is defined by chaos. An unexpected failure sends you scrambling for emergency service, paying premium rates for after-hours repairs, and dealing with significant downtime that can ripple through your entire business.

A preventative maintenance plan, on the other hand, puts you firmly in control. Instead of reacting to disasters, you’re actively working to stop them from ever happening. The shift from reactive chaos to proactive control delivers tangible benefits that go far beyond just avoiding a few breakdowns.

Extended Equipment Lifespan: Regular service catches and corrects minor issues before they can snowball into catastrophic component failures. This simple step can dramatically prolong the life of your very expensive equipment.

Improved Energy Efficiency: Clean coils, calibrated thermostats, and properly functioning components mean your system isn't working harder than it needs to. The result? Lower monthly energy bills. For instance, just keeping condenser coils clean in a building with 60 tons of cooling can save over 35,000 kWh in just three months.

Enhanced Air Quality: Routine filter changes and system cleanings are absolutely critical for maintaining healthy indoor air quality, which directly impacts the well-being and productivity of everyone inside your building.

A well-maintained system isn't just about comfort; it's about creating a safe, efficient, and reliable environment. It's the foundation of a building that works for its occupants, not against them.

A Growing Global Trend

This proactive mindset isn't just a local best practice; it reflects a massive global shift. The market for HVAC maintenance services, which includes commercial HVAC preventative maintenance, was valued at a staggering $82,929.5 million in 2024. That number is projected to climb to $116,272.6 million by 2030.

What's driving this growth? It's a worldwide push for greater energy efficiency, stricter environmental regulations, and the adoption of more advanced HVAC technologies that demand expert care. As buildings get smarter and sustainability becomes a bigger priority, professional maintenance is no longer optional—it's essential. You can get more insights on this trend from market analyses like those on grandviewresearch.com.

By implementing a structured maintenance plan, you’re aligning your facility with modern operational standards, protecting your investment today while preparing for the demands of the future.

Building Your HVAC Preventative Maintenance Framework

A top-tier commercial hvac preventative maintenance program doesn’t just happen; it's carefully built on a solid, documented foundation. The goal is to transform a chaotic, reactive cycle of repairs into a predictable, well-oiled machine that protects both your equipment and your budget. It all starts by getting organized.

You can't effectively maintain what you haven't properly identified. The first real step is to conduct a thorough inventory of every single piece of HVAC equipment you manage. This isn't just a quick head count; think of it as a detailed data-gathering mission.

For each unit, you need to log:

Asset ID: A unique tag for easy tracking.

Make and Model: Absolutely essential for ordering the right parts and finding manufacturer specs.

Serial Number: The key to warranty claims and specific service histories.

Installation Date and Age: This helps you anticipate end-of-life and budget for replacements.

Location: Where is it, exactly? (e.g., Roof-West, Mech Room 3).

Service History: A running log of every repair, maintenance visit, and part replacement.

This inventory becomes your single source of truth. No more guesswork, just a clear, comprehensive map of your entire HVAC ecosystem.

Tailoring Your Maintenance Schedule

Once your inventory is complete, you can ditch the one-size-fits-all approach. Not every unit needs the same level of attention. Customizing your maintenance schedule based on specific factors is where you start to see real optimization in both performance and cost.

Think about the difference between a retail store in Tucson and a climate-controlled data center. That retail rooftop unit is battling extreme summer heat and monsoon dust, which means it needs more frequent filter changes and coil cleanings. Meanwhile, the data center's system might be in a cleaner indoor space, but it runs 24/7 under a critical load. This demands more frequent electrical component checks and redundant system tests to prevent even a moment of downtime.

A smart schedule is tiered, usually with monthly, quarterly, and annual tasks. For a deeper dive into creating this, take a look at our guide on building your essential HVAC maintenance schedule. This layered approach ensures routine checks happen often, while more intensive servicing is scheduled at the right times.

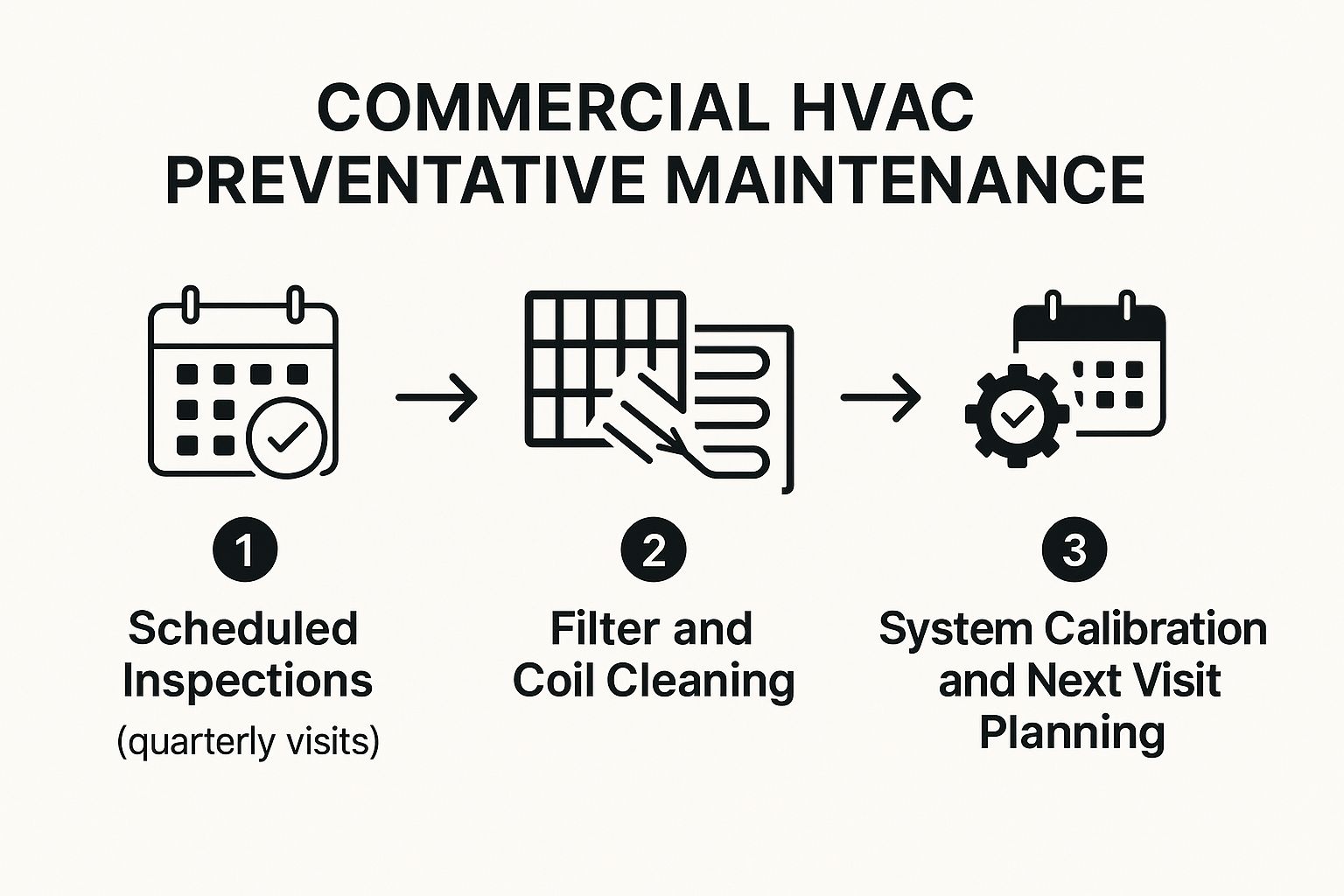

Take a look at the fundamental flow of a typical maintenance cycle.

As you can see, scheduled inspections lead to specific actions like cleaning. This work then informs calibration and future planning, creating a loop of continuous improvement.

A great maintenance plan often breaks down tasks by season to align with the system's workload. Here’s a sample of what that might look like:

Seasonal HVAC Preventative Maintenance Checklist

This table offers a simplified look at how you might divide key maintenance tasks across the year, ensuring your systems are ready for peak demand.

Task Category | Spring/Summer Tasks | Fall/Winter Tasks |

|---|---|---|

Filters | Check and replace air filters monthly during high-use periods. | Check and replace filters quarterly or as needed. |

Coils | Inspect and clean condenser and evaporator coils. | Inspect coils for dirt and debris. |

Electrical | Check and tighten all electrical connections. | Inspect wiring and test capacitors. |

Condensate | Clear condensate drain lines to prevent clogs and water damage. | Inspect drain pan and lines for potential blockages. |

System Test | Test thermostat calibration and system cooling cycle. | Test heating cycle and safety controls. |

Refrigerant | Check refrigerant levels (by a certified technician). | N/A for most heating systems unless it's a heat pump. |

Belts & Pulleys | Inspect belts for wear and tear; check pulley alignment. | Inspect belts for cracks and tension. |

By following a seasonal checklist, you’re not just reacting to problems—you’re actively preventing them before they can start.

Choosing the Right Tracking Tools

Your detailed inventory and tailored schedules are powerful, but only if you use them consistently. A quarterly inspection forgotten because it was on a sticky note that fell off the wall is a failure waiting to happen. You need a reliable system.

The tool you pick can be as simple or as complex as your operation requires.

Robust Spreadsheets: For smaller facilities with just a handful of units, a well-organized spreadsheet in Google Sheets or Excel can work perfectly. You can create different tabs for your asset list, maintenance schedules, and service logs.

Dedicated CMMS Software: For larger portfolios or facilities with complex needs, a Computerized Maintenance Management System (CMMS) is a game-changer. These platforms automate scheduling, generate work orders, track costs, and give you detailed analytics on equipment performance.

The best tool is the one your team will actually use. Whether it's a shared spreadsheet or sophisticated software, consistency is what turns a plan on paper into an effective, dynamic operational strategy.

No matter which tool you choose, the goal is the same: provide visibility, ensure accountability, and create a historical record that helps you make smarter decisions. For example, if your CMMS data shows that one particular rooftop unit has needed the same expensive repair three times in a year, you have a solid, data-backed case for a full replacement. This proactive, data-driven mindset is the core of any modern, effective commercial HVAC preventative maintenance program.

With a solid maintenance plan in hand, it's time to roll up our sleeves and get into the nitty-gritty. This is where the rubber meets the road, the essential, recurring tasks that form the backbone of any successful commercial HVAC preventative maintenance program.

Understanding what your technicians are doing on the roof (and why it matters) is huge. It moves you from being a passive client to an active partner in managing your building's most critical assets. Each check and adjustment directly heads off a potential failure, an efficiency drain, or a budget-busting repair.

Let's walk through the core activities that truly protect your investment.

The Foundation: Air Filters and Coils

In the world of HVAC, the relationship between air filters and coils is everything. It's simple: a dirty filter leads to dirty coils. And dirty coils are a one-way ticket to high energy bills and strained equipment.

When a filter gets clogged, it chokes the system. The fan motor has to work overtime just to pull air through, which burns more electricity and puts incredible stress on the motor, setting it up for an early grave. Worse, the dust and debris that sneak past that clogged filter don't just disappear; they get caked onto the evaporator and condenser coils.

This layer of grime acts like a winter coat on the coils, making it nearly impossible for them to transfer heat effectively. The system is forced to run longer and harder to do its job. In fact, one study showed that just keeping the condenser coils clean on a 60-ton system can save over 35,600 kWh in only three months. That's a serious number.

I always tell clients to think of HVAC coils like the radiator in their car. If that radiator is caked in mud, the engine overheats in a hurry. Your HVAC system isn't any different. Clean coils are non-negotiable for system health.

Here in Arizona, some of our clients in dustier industrial areas need monthly filter changes. For an office park, a quarterly schedule might be fine. This one simple task is your absolute first line of defense.

Heading Off Water Damage and Mechanical Wear

Beyond just airflow, a couple of other key areas need constant vigilance to prevent both sudden disasters and slow, creeping decline. I'm talking about drain lines and mechanical parts like belts and pulleys.

Condensate drain lines are the unsung heroes of the cooling process, whisking away all that moisture pulled from the air. But over time, they can get clogged with a nasty sludge of algae and debris. When that happens, water backs up and overflows the drain pan, which can lead to catastrophic water damage to your ceilings, walls, or inventory below. A quick, regular check to ensure these lines are clear is cheap insurance against a very expensive mess.

At the same time, many commercial air handlers rely on a simple belt to connect the motor to the blower fan. These are wear items, just like tires on a car.

During an inspection, a good technician is looking at a few key things:

Belt Tension: Is it too loose? It'll slip, squeal, and reduce airflow. Too tight? It's putting massive strain on the bearings of both the motor and the fan.

Signs of Wear: We look for any cracks, fraying, or a glazed, shiny surface. These are tell-tale signs the belt is about to fail and needs to be replaced before it snaps.

Pulley Alignment: If the pulleys are misaligned, the belt will wear out unevenly and can damage the motor and blower shafts themselves.

These might seem like small details, but they prevent the abrupt failure of your air delivery system, which means no emergency calls and no uncomfortable tenants.

Calibrating the Brains of the Operation

Finally, you can't forget about the system's controls and electrical components. A thermostat that’s off by just a couple of degrees might not sound like a big deal, but it can cause the system to run constantly, wasting a surprising amount of energy.

Our technicians will verify that the thermostat is reading accurately and that the system is responding correctly. Just as important is inspecting and tightening all the electrical connections. A single loose wire can cause voltage drops, fry a control board, or worse, become a serious fire hazard.

To get a complete picture of all these crucial touchpoints, our **HVAC preventative maintenance checklist with 7 tips for 2025** is a great resource. Use it to guide your next conversation with your service provider. When you understand these essential tasks, you're better equipped to ensure your maintenance plan is truly delivering the value you pay for.

Proving the Value: How to Quantify the ROI of Your Maintenance Program

Sooner or later, every facility manager has to answer the big question from the decision-makers: "What's the return on this?" When you're justifying the budget for commercial HVAC preventative maintenance, vague promises about "better performance" just won't fly. You have to speak their language—the language of hard numbers, concrete cost reductions, and a measurable return on investment (ROI).

Let's be clear: this isn't an expense. It's a strategic investment, and a smart one at that. It’s time to move beyond the abstract benefits and get into the real, tangible financial wins that a well-run maintenance plan brings to the table.

Slashing Expensive Emergency Repairs

The most immediate and dramatic payback you'll see comes from avoiding those gut-wrenching, unplanned breakdowns. Let's face it, reactive maintenance is a budget killer. You’re not just paying for a repair; you’re paying a premium for emergency, after-hours service, which can easily cost two to three times more than a scheduled visit.

Think about a classic scenario: a rooftop unit’s compressor gives out on the hottest day of the summer. That emergency call is going to run you thousands of dollars, no question. A solid preventative maintenance plan, however, would have likely spotted the warning signs—like weird electrical draws or low refrigerant levels—months ago. That turns a crisis into a simple, affordable fix during a routine check-up.

A single avoided emergency call can often pay for an entire year's worth of a maintenance agreement. It's the ultimate defense against budget-destroying surprises.

Driving Down Monthly Utility Bills

It really is this simple: optimized systems use less energy. When your HVAC equipment is clean, calibrated, and running as it should, it doesn’t have to fight to maintain the right temperature. This translates directly into lower monthly utility bills; a clear, consistent, and easily tracked financial return.

For instance, something as basic as dirty condenser coils forces the system to run longer and harder just to get rid of heat, which spikes electricity use. A proactive plan ensures those coils are cleaned regularly, maximizing efficiency. The same logic applies to calibrated thermostats, properly tensioned belts, and clean filters. Each task methodically chips away at energy waste, and those savings add up in a big way over the course of a year.

The Overlooked Financial Gain: Tenant Retention

Here’s an ROI metric that a lot of facility managers miss: tenant retention. Uncomfortable tenants are unhappy tenants, and unhappy tenants are the ones who don't renew their leases. If the phone is constantly ringing with complaints about the building being too hot, too cold, or having stuffy air, you're creating a major incentive for them to leave.

And what does that turnover actually cost you?

Lost Rent: Every month a space sits empty is a direct hit to your revenue.

Marketing Costs: You have to spend money to advertise and show the vacant space.

Broker Commissions: Finding a new tenant almost always involves hefty fees.

Build-Out Costs: New tenants often require expensive modifications to the space before they move in.

Reliable, effective HVAC is a cornerstone of tenant satisfaction. A comfortable and healthy indoor environment isn't just a perk; it's a powerful retention tool. By investing in preventative maintenance, you're also investing in a stable, predictable revenue stream. The impact of a well-maintained system reaches far beyond the mechanical room, and you can see how this plays out in other property types by reviewing the top 8 benefits of HVAC maintenance for Tucson homes in 2025.

Hard Data Backs Up the Savings

Look, the financial case for proactive care isn't just theory, it's backed by real-world data. Study after study confirms that a structured commercial HVAC preventative maintenance program is vastly more cost-effective than just waiting for things to break.

In fact, one major study that tracked over 100,000 rental units discovered that putting a preventative maintenance program in place cut HVAC service requests by a massive 31-50%. On top of that, this proactive approach delivers an average cost savings of 8-12% compared to a reactive, "break-fix" model. You can dig into these findings and more at worktrek.com.

When you walk into a budget meeting armed with data like this, the conversation changes. Your maintenance plan stops looking like an expense and starts looking like what it really is: a proven cost-reduction strategy.

Using Technology For Smarter HVAC Management

The days of managing a complex commercial HVAC system with just a clipboard and a paper checklist are fading fast. Today, a proactive commercial HVAC preventative maintenance strategy is powered by data, giving you an unprecedented look into your equipment's health and performance. This shift from manual tracking to smart management simply helps you work smarter, not harder.

Modern tech lets you get out of a reactive posture and into a predictive one. Instead of waiting for a quarterly inspection to maybe find a problem, you can get real-time alerts about potential issues before they become disasters. This capability is a game-changer for protecting your assets and keeping your operations running smoothly.

The Power of Real-Time Data

The heart of this modern approach is a combination of Building Management Systems (BMS) and the Internet of Things (IoT) sensors. Think of these systems as the central nervous system for your facility, constantly gathering and analyzing performance data from every connected piece of equipment.

Here’s a real-world scenario I see all the time: An IoT sensor on a critical rooftop air handler detects a subtle, but persistent, increase in motor vibrations. This tiny deviation from the normal baseline automatically triggers an alert, sending it straight to your facility manager’s dashboard and your HVAC contractor.

Without this tech, you'd likely discover the problem after the motor completely fails, probably during a sweltering heatwave. Instead, you can schedule a technician to investigate. The tech finds that the motor bearings are starting to wear out. A simple, low-cost bearing replacement is done during planned downtime, preventing a catastrophic failure that would have cost thousands in emergency repairs and lost productivity.

By turning raw data into actionable intelligence, you stop managing crises and start preventing them. This predictive power is the key to maximizing uptime and minimizing operational disruptions.

This data-driven method also aligns perfectly with broader smart building initiatives, creating a more responsive and efficient facility from top to bottom.

Integrating Automation for Greater Efficiency

Beyond just sending alerts, technology can automate huge parts of the maintenance process. When you integrate a modern Computerized Maintenance Management System (CMMS) with your BMS, it can automatically generate work orders based on sensor data or pre-set schedules.

Consider these practical applications:

Automated Scheduling: The system can schedule routine tasks like filter changes based on actual runtime hours, not just a calendar date. This means filters get replaced exactly when needed.

Predictive Part Ordering: If a sensor indicates a component is nearing the end of its typical lifespan, the system can flag it for replacement during the next service visit, ensuring the technician arrives with the right part already in hand.

Performance Benchmarking: You can track energy consumption against historical data and even similar buildings, quickly spotting underperforming units that need attention. Our guide on improving your HVAC system efficiency digs deeper into these strategies.

This level of automation cuts down on human error, optimizes your team's time, and gives you a clear, documented history of every action taken on your equipment.

The Growing Market for Smart Maintenance

This isn't some niche trend; it's a massive force driving the industry forward. The global market for commercial HVAC preventative maintenance is seeing major growth, largely because of the high demand for energy-efficient systems and the widespread adoption of smart building tech.

As detailed in this comprehensive report, this market is on a strong upward trajectory. It’s fueled by a focus on using automation to boost both sustainability and operational performance.

When you adopt these tools, you aren't just keeping up. You're positioning your facility at the forefront of modern building management. The result is a maintenance program that's more efficient, more effective, and ultimately, more valuable to your organization's bottom line. Technology finally gives you the tools to get ahead of problems, ensuring your systems deliver reliable comfort and peak performance year-round.

Answering Your Top Commercial HVAC Maintenance Questions

When you're managing a commercial property, the HVAC system can feel like a constant source of questions. As a facility manager, you need clear, direct answers to build an effective commercial hvac preventative maintenance plan. Let's tackle some of the most common questions we get from clients, giving you the straightforward advice you need to move forward with confidence.

One of the first things people ask is about service frequency. It's a great question, because there's no single right answer—a one-size-fits-all approach just doesn't cut it for complex commercial buildings.

How Often Should My Commercial HVAC System Be Serviced?

Honestly, the "perfect" service schedule really depends on your specific equipment, its age, and the environment it's running in. A system in a dusty manufacturing plant is going to need a lot more hands-on attention than one humming away in a pristine office building.

As a solid rule of thumb, we recommend professional, comprehensive service at least twice a year. Think once in the spring to prep for the cooling season and again in the fall before the heat kicks on. But if your HVAC is critical to your operations or it’s in a tough environment, quarterly inspections are a much safer bet. And don't forget the simple stuff; basic tasks like changing air filters might need to be done monthly.

What’s the Real Difference Between Preventative and Reactive Maintenance?

The philosophy behind your maintenance strategy is a game-changer. The two main paths, preventative and reactive, will have completely different effects on your budget, equipment life, and day-to-day operations.

Preventative maintenance is all about being proactive. It means sticking to a schedule of regular inspections, cleanings, and tune-ups to keep your equipment running at its best. The whole point is to find and fix small issues before they snowball into a catastrophic failure. It's about stopping problems before they start.

Reactive maintenance, sometimes called breakdown maintenance, is the polar opposite. It’s the "if it ain't broke, don't fix it" approach. You only call for service after a unit has already malfunctioned or died completely. While this might look cheaper on paper since you avoid upfront service costs, it almost always ends in pricier emergency repairs, frustrating downtime, and a much shorter lifespan for your equipment.

Can We Handle HVAC Maintenance In-House or Should We Hire a Pro?

This is a classic question, and the best answer for most facilities is a smart hybrid approach. You can leverage the skills of both your on-site team and a specialized commercial HVAC contractor.

Your in-house staff is perfectly capable of handling the simple, frequent tasks. This usually includes:

Regularly inspecting and changing air filters.

Cleaning around indoor and outdoor units to keep them free of debris.

Keeping an eye out for obvious problems like leaks or weird noises.

Making sure thermostats are set correctly.

However, the more technical and critical work should always be left to a certified, insured commercial HVAC contractor. They have the specialized tools, in-depth training, and essential certifications to handle complex systems safely and correctly. This keeps you compliant with regulations and protects your warranties.

A professional technician handles the critical jobs; things like checking refrigerant levels, testing electrical components, inspecting ductwork for costly leaks, and running deep system diagnostics that are far beyond the scope of general maintenance staff.

How Much Does a Commercial HVAC Maintenance Plan Cost?

The cost of a commercial maintenance plan can vary quite a bit. The price really hinges on the size of your facility, the number and type of HVAC units you have, their age, and exactly what services are included in the agreement.

A basic plan for a small commercial space might run a few hundred dollars per visit. In contrast, a comprehensive plan for a large facility with a dozen complex systems could easily be several thousand dollars a year. It’s crucial to get detailed quotes from a few qualified contractors. But remember, while cost is a factor, the real focus should be on value. Thinking about managing these expenses? It's worth looking into different payment structures; you can learn more about [HVAC financing options and ways to save on your system](https://www.covenantairesolutions.com/post/hvac-financing-options-easy-ways-to-save-on-your-system).

A slightly more expensive plan that prevents just one major emergency repair will pay for itself many times over. It's a smart investment in your building's future.

At Covenant Aire Solutions, we build transparent, detailed maintenance agreements that are designed for the unique demands of your commercial property. Contact us today to schedule an assessment and get a clear, upfront quote for a preventative maintenance plan that protects your investment.