A Homeowner's Guide to Furnace Blower Motor Troubleshooting

- Jan 13

- 13 min read

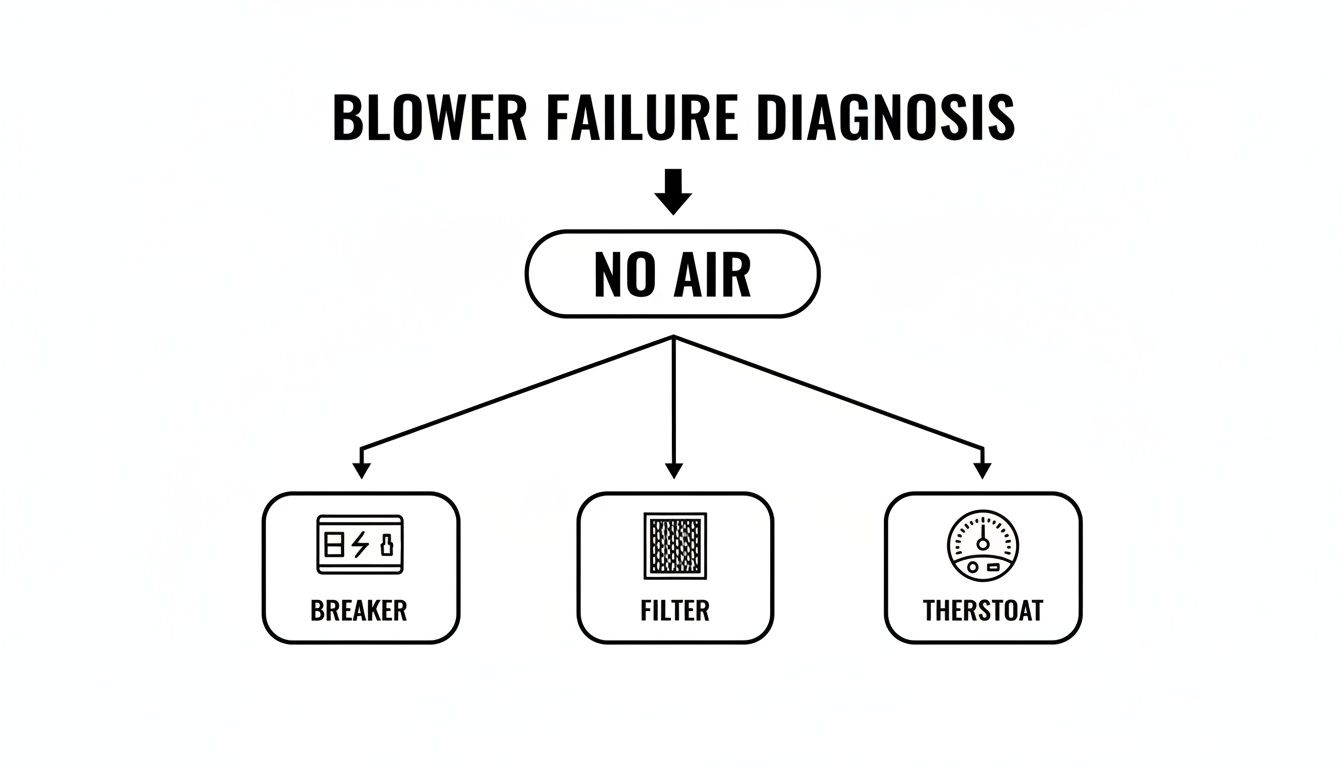

When your furnace fires up but you feel absolutely nothing coming from the vents, the blower motor is almost always the culprit. Before you start dreading a costly repair, know that troubleshooting a furnace blower motor often begins with checking three of the most common, and simplest, issues: a tripped circuit breaker, a severely clogged air filter, or an incorrect thermostat setting.

Honestly, you'd be surprised how many times one of these simple checks solves the problem in minutes, no special tools required.

Why Is My Furnace Blower Not Working?

Hearing the furnace kick on without any resulting airflow is a classic sign of a blower problem. It’s a frustrating spot to be in, especially on a chilly Tucson night, but it doesn't automatically mean a major mechanical failure. More often than not, the solution is much simpler than homeowners expect. The key is to walk through the possibilities systematically instead of jumping to the worst-case scenario.

Before you even think about touching the furnace panel, let's cover the basics. These foundational checks are the fastest way to rule out the simple oversights that keep a blower from doing its job. A huge number of our service calls could be avoided by running through these quick steps first.

Common Culprits Behind a Silent Blower

A few key issues are responsible for the vast majority of blower failures. Power interruptions are at the top of the list; a tripped circuit breaker simply cuts the electricity to the furnace, so the blower motor never gets the signal to start.

Another frequent offender is a clogged air filter. If it gets dirty enough, it can restrict airflow so much that the furnace’s own safety features shut the whole system down to prevent overheating. And of course, a simple mistake at the thermostat, like having the fan set to "OFF" or the system mode on the wrong setting, can be the root cause.

This flowchart gives you a great visual of the first steps you should take when you realize there's no air coming from your vents.

As the chart shows, your troubleshooting journey should always start with power, airflow restrictions, and what the thermostat is telling the system to do.

Your First Diagnostic Checklist

To make this even easier, here's a quick table to help you connect what you're experiencing with the most likely cause. Think of it as your first line of defense before assuming a more serious mechanical issue is at play.

Quick Blower Motor Diagnostic Checklist

Symptom | Most Likely Cause | Your Next Action |

|---|---|---|

Furnace is completely silent. | Tripped Circuit Breaker | Head to your electrical panel and find the breaker labeled "Furnace" or "HVAC." Flip it all the way to the "OFF" position, then firmly back to "ON" to reset it. |

Furnace runs briefly, then shuts off. | Severely Clogged Air Filter | Turn off the furnace at the thermostat. Locate your filter access panel, pull out the air filter, and take a look. If it's caked in dust or looks gray, it's time for a new one. |

Furnace doesn't respond to temperature changes. | Incorrect Thermostat Setting | Check that your thermostat is set to "HEAT" and the fan is set to "AUTO." If it’s a battery-powered model, now is a great time to pop in some fresh batteries. |

Properly diagnosing the airflow of a furnace is critical, as blockages can cause serious long-term damage. These initial steps empower you to quickly find and fix the most common problems plaguing your furnace blower.

Essential Safety Steps and Tools for the Job

Alright, before you even think about grabbing a screwdriver and popping open your furnace’s access panel, we need to talk about safety. This isn't just a suggestion, it's the absolute first priority. You’re dealing with components tied directly into your home's main electrical system, and that demands respect.

The single most critical step in any furnace blower motor troubleshooting is to kill the power completely. And no, just flipping the thermostat to "off" doesn't cut it.

You need to walk over to your main electrical panel, find the circuit breaker labeled "Furnace," "Air Handler," or "HVAC," and switch it firmly to the "OFF" position. This is the only way to guarantee the unit won't fire up unexpectedly while your hands are inside.

Here's a pro tip we live by: always double-check. Grab a voltage tester or multimeter and touch the probes to the furnace terminals. Seeing that "zero" reading provides total peace of mind that the power is truly, completely off.

Once you’re confident the unit is dead, it's time to gather your tools. Having the right gear ready saves you from running back and forth to the garage and ensures you can perform your tests accurately.

Your Essential Troubleshooting Toolkit

You don't need a whole workshop, but a few specific tools are non-negotiable for getting to the bottom of the issue.

Multimeter: This is your best friend for this job. It's the only way to safely test for voltage, check the run capacitor's health, and confirm electrical continuity.

Nut Drivers or Socket Set: The access panels on most furnaces are held on by hex-head screws. A 1/4-inch and 5/16-inch nut driver will get you into almost any unit out there.

Insulated Screwdrivers: You'll want a good set of both Phillips-head and flat-head screwdrivers for various brackets and components inside.

Safety Gear: Never skip this. A good pair of insulated gloves and some safety glasses will protect you from sharp sheet metal edges and any lingering electrical risks.

Getting comfortable with the maze of wires inside is also a huge help. For a detailed guide on that, check out our post on https://www.covenantairesolutions.com/post/how-to-read-hvac-wiring-diagrams-explained. And since you're working with a gas furnace, being aware of all potential hazards is just smart; brushing up on how to detect gas leaks is an excellent extra safety measure.

Decoding Blower Symptoms From Weak Airflow to Strange Noises

Alright, you've confirmed the furnace has power, so now it’s time to play detective. Furnace blower motor troubleshooting is all about listening to what your system is trying to tell you. Every symptom, from weak airflow to a strange new noise, is a clue.

These issues don't just pop up for no reason; they're your furnace's way of signaling that something's off. By connecting what you're seeing, hearing, and feeling to the likely mechanical or electrical cause, you can stop guessing and start focusing your efforts where they'll actually make a difference.

The Number One Cause of Weak Airflow

When the air coming from your vents feels more like a whisper than a gust, the first thing you should check is the air filter. Seriously. A dirty, clogged filter is far and away the most common culprit behind airflow problems, especially here in dusty Tucson. Think of the filter as your system's lungs; if it can't breathe, nothing else works right.

We've seen it time and time again: dirty filters are to blame for up to 70% of initial weak airflow complaints. A single clogged filter can choke off airflow by as much as 50%, forcing the motor to strain itself just to do its job. That strain doesn't just jack up your energy use by an average of 15%; it also dramatically shortens the motor's lifespan.

When a furnace isn't blowing hot air effectively, the problem often isn't the heat source itself, but the component responsible for moving that heat. Addressing airflow restrictions is a critical first step. You might be interested in our guide covering what to do when your furnace is not blowing hot air.

Interpreting Unusual Blower Motor Noises

Beyond just how much air is moving, the sounds your furnace makes are huge diagnostic clues. Don't ever just turn up the TV to ignore a new noise. These sounds are often the earliest warning signs of a coming mechanical failure.

Here’s a quick rundown of what to listen for:

Squealing or Screeching: That high-pitched wail usually points to a worn-out belt, common in older belt-drive blower systems. It can also mean the motor's bearings are crying out for lubrication or are on their last legs.

Grinding or Scraping: This is a bad one. It’s a harsh, metallic sound that often means the motor bearings have completely failed. It could also be that the blower wheel itself has broken loose and is scraping against the inside of the housing. If you hear this, shut the system down immediately to prevent more damage.

Loud Humming: A strong, consistent hum, especially if the motor is trying but failing to start, is a classic symptom of a bad run capacitor. The motor is getting juice, but it's missing that initial electrical "kick" it needs to get spinning.

By methodically matching these symptoms to their most likely causes, you can narrow down the problem quickly. This logical approach ensures you check the simple, common-sense stuff first before diving into the more complex electrical and mechanical parts.

Alright, you've listened to your furnace and have a few ideas about what's going on. Now it's time to roll up your sleeves and confirm your suspicions with some hands-on electrical and mechanical checks. This is where we shift from just observing the symptoms to actually using our tools to pinpoint exactly which part has failed.

Let's be clear, though: safety comes first. Any time you're about to work on the electrical side of your furnace, you need to know what you're doing. A great resource is the official NFPA 70E Electrical Safety Guidance. Before you even think about touching a wire, kill the power at the breaker. No exceptions.

Testing the Run Capacitor

First up is a surprisingly common troublemaker: the run capacitor. This small, cylinder-shaped part is essentially a tiny battery that gives the blower motor the jolt it needs to start spinning and keeps it running smoothly. When it goes bad, you often get that classic humming sound: the motor wants to start but just can't get going.

In my experience, a failing capacitor is responsible for about 25-35% of blower startup failures, especially in furnaces that are 10-15 years old. The intense Tucson heat really puts a strain on these components, causing them to wear out faster.

Here’s how to check it:

Power Off: I know I already said it, but double-check that the breaker is off.

Discharge It: Capacitors can hold a dangerous electrical charge even when the power is off. Grab a screwdriver with an insulated handle and carefully touch the metal shaft across both metal terminals at the same time. You might see a small spark; that's the stored energy safely discharging.

Test with a Multimeter: Switch your multimeter to the microfarads setting (look for μF or MFD). Touch one probe to each terminal. The number on the screen should be within +/- 10% of the rating printed right on the side of the capacitor. If it's way off, you've found your problem.

Verifying Voltage at the Motor

If the capacitor tests out fine, the next logical step is to see if electricity is even getting to the motor. This check helps you figure out if the problem is the motor itself or something further upstream, like the control board.

For this test, you'll need to turn the power back on temporarily. Go ahead and set your thermostat to call for heat or fan. Now, carefully set your multimeter to AC voltage and test the terminals right on the blower motor where the power wires connect. You should get a reading of around 115V to 120V.

If you see 120V at the motor but it’s still not running (and you've already confirmed the capacitor is good), then the motor itself is almost certainly dead. On the flip side, if you get no voltage reading, the problem lies elsewhere, likely a bad relay or a fried control board.

Inspecting Mechanical Components

Not every blower problem is electrical. Sometimes, good old-fashioned mechanical issues are the culprit, so a quick physical inspection is always a good idea.

Take a look at the blower wheel, the part that looks like a hamster wheel, often called a "squirrel cage." Over the years, it can get caked with a thick layer of dust and grime. This buildup throws the wheel off balance, causing vibrations, and can dramatically restrict airflow. A good cleaning with a stiff brush and a vacuum can work wonders.

If you have an older furnace, it might have a belt-drive system. Find the belt that connects the motor to the blower wheel. It should have about a half-inch of play when you press down on it. If it's too loose, it'll slip and squeal. If it's too tight, it will put a ton of strain on the motor bearings, leading to premature failure.

These hands-on checks give you the solid evidence you need to move from guessing to knowing. And by the way, don't get the blower motor confused with the inducer motor; they do very different jobs. If you're curious, we have a whole guide explaining what a furnace inducer motor does.

Deciding Between a DIY Fix and Calling a Professional

Knowing your limits is probably the most important part of any home repair, and tinkering with your furnace blower motor is no different. It’s crucial to draw a clear line between what you can safely handle and what really needs an expert’s touch. The good news is some tasks are definitely within reach for a handy homeowner.

Simple fixes, for instance, like swapping out a dirty air filter or tightening a loose fan belt on an older furnace, are great DIY jobs. If you're comfortable with electrical safety protocols, even replacing an accessible run capacitor can be a totally manageable weekend project that'll save you a good chunk of change.

These smaller jobs can often get things running again without you having to schedule a service call. That said, there are some very clear red flags that mean it's time to put down the tools and pick up the phone.

When to Immediately Call a Professional

Some symptoms and situations just aren't worth the risk. They go way beyond a simple fix and demand the trained eye of a certified HVAC technician. Trying to tackle these repairs without the right training can lead to even more damage, serious safety hazards, or a botched job that just fails again in a few weeks.

You should stop what you're doing and call for professional help if you run into any of these scenarios:

Burning Smells: Any kind of sharp, acrid, or electrical burning odor is a major warning. This could mean the motor is overheating or wire insulation is melting, a serious fire risk. Don't hesitate on this one.

Complex Wiring Issues: If your multimeter tests show problems coming from the control board, or if you uncover wiring that’s damaged, frayed, or just plain confusing, it’s time to stop.

A Damaged Blower Wheel: A bent, broken, or wobbly blower wheel isn’t a simple swap. It requires a precise replacement and rebalancing job that is absolutely best left to a pro.

Complete Motor Replacement: Pulling out and installing an entire blower motor assembly is a complex job. It involves disconnecting intricate wiring, making sure the new motor is mounted perfectly, and guaranteeing proper alignment with the blower wheel.

Worn-out blower bearings and frayed belts contribute to 20% of noisy furnace operations and airflow inconsistencies. Our internal data and industry analyses show these mechanical faults are found in 1 out of every 5 service calls for systems over 12 years old. In Arizona’s dusty conditions, these issues can pop up even faster, making a professional diagnosis all the more critical.

The Value of a Professional Repair

When you call in a pro, you’re getting more than just a repair, you’re getting peace of mind. A certified technician from Covenant Aire Solutions doesn't just get the job done right; they provide a warrantied repair that protects your investment. We make sure every component is working together exactly as it should, protecting both your system and your family.

To learn more about keeping your system in prime condition year-round, check out our guide on your essential HVAC maintenance schedule.

Common Questions About Furnace Blower Motors

Even after going through the troubleshooting steps, it’s perfectly normal to still have a few questions lingering. When it comes to something as important as your furnace, you want to be sure. Here are some straightforward answers to the questions we hear most often from homeowners here in Tucson.

How Much Does It Cost to Replace a Furnace Blower Motor in Tucson?

The price tag on a blower motor replacement can swing quite a bit, and it mostly comes down to the type of motor your furnace uses. An older, standard PSC motor is going to be less expensive than a modern, high-efficiency ECM (Electronically Commuted Motor).

For a full replacement here in Tucson, you can generally expect the cost to land somewhere between $800 and $1,500. That price typically covers both the new motor itself and the professional labor to get it installed safely and correctly.

On the other hand, if the problem is just a bad capacitor, you’re looking at a much more wallet-friendly fix. A capacitor replacement usually runs from $150 to $300. No matter what, always make sure you get a clear, upfront quote before any work starts so there are no surprises later.

Can a Bad Blower Motor Cause My Furnace to Overheat?

Absolutely. In fact, a failing blower motor is one of the top reasons a furnace will overheat. The motor's entire job is to move air across the heat exchanger, sending that warm air into your home. If that airflow suddenly stops, all the intense heat generated by the burners has nowhere to escape.

This is a dangerous situation, and your furnace knows it. The rapid heat buildup triggers a safety feature called the high-limit switch, which shuts the whole system down to prevent a fire or, at the very least, catastrophic damage to the heat exchanger.

If you’ve noticed your furnace kicks on for a few minutes, shuts off abruptly, and then tries again a little later, that’s a classic case of "short cycling." A bad blower motor is a very common culprit behind this inefficient and potentially hazardous behavior.

How Can I Make My Furnace Blower Motor Last Longer?

Preventive maintenance is, without a doubt, the best way to get the longest possible life out of your blower motor. The number one thing you can do is change your air filter regularly; every one to three months is a good rule of thumb for most homes. A clean filter lets air pass through easily, which means the motor doesn't have to strain itself to do its job.

Beyond that, scheduling an annual professional HVAC tune-up is key. A certified technician can handle the important tasks that homeowners can't, including:

Cleaning the blower wheel and the entire housing assembly.

Lubricating the motor bearings (if your model has ports for it).

Checking and tightening all electrical connections for safety.

Testing the run capacitor to confirm it’s still within its specified electrical range.

This kind of proactive care is what helps a motor reach its full expected lifespan of 15 to 20 years.

Is a Loud Furnace Blower Motor Dangerous?

You should never ignore a loud blower motor. Think of it as a serious warning sign that something is mechanically wrong. Grinding, scraping, or high-pitched squealing noises are often the sound of failing motor bearings or a damaged, out-of-balance blower wheel.

If one of these parts fails completely while spinning at hundreds of RPMs, it can break apart and cause a ton of collateral damage to other expensive components inside your furnace. If you hear any of these harsh, unusual sounds, the safest move is to shut the system off at the breaker and call a professional for an inspection right away. Acting fast can be the difference between a targeted repair and a catastrophic failure.

When your furnace blower motor problem is more than a simple DIY fix, don't gamble with your comfort or safety. The certified professionals at Covenant Aire Solutions are here to provide honest diagnostics and reliable repairs throughout the Tucson area. Contact us today for fast, friendly service you can trust.