What is a furnace Inducer Motor? A Quick Guide

- Nov 6, 2025

- 14 min read

Updated: Nov 7, 2025

A furnace inducer motor is one of those critical, behind-the-scenes parts in modern furnaces that ensures everything runs safely and efficiently. At its core, it's a small motor with a fan attached that has one primary job: to vent harmful exhaust gases out of your home before the burners ever kick on. This is the very first step in the heating sequence, and it's non-negotiable for a safe startup.

Understanding the Furnace Inducer Motor

Think of the furnace inducer motor as the lungs of your heating system. Before your furnace can "breathe in" fresh air to start the combustion process, it must first "exhale" any lingering, dangerous gases left over from the last heating cycle. Without this crucial pre-purge, your furnace’s safety controls will prevent it from moving on to the next step: igniting the burners.

This component serves a dual purpose that's absolutely essential for both safety and performance. Its main job is to create a draft, which pulls combustion byproducts like carbon monoxide through the heat exchanger and then pushes them safely outside through a flue pipe. This single function is what truly separates modern, high-efficiency furnaces from older, less safe models.

From Natural Draft to Modern Efficiency

The furnace inducer motor is a relatively recent innovation in home heating. It started showing up in residential furnaces in the early 1990s, largely as a direct response to new federal efficiency standards. Before 1992, most furnaces relied on a "natural draft" system, but new regulations required a minimum Annual Fuel Utilization Efficiency (AFUE) of 78%. This demanded a more active approach to venting, which gave rise to the inducer motor. You can learn more about how these innovations led to different residential HVAC system types in our detailed guide.

This was a major shift. By mechanically controlling the exhaust, manufacturers could design more sophisticated heat exchangers that squeezed every last bit of heat from the combustion process, dramatically improving efficiency.

Key Takeaway: The inducer motor is the gatekeeper of your furnace's operation. It must run successfully and prove there is a clear path for exhaust before the system's safety sensors will allow the gas valve to open and ignition to occur.

To make it even clearer, let's break down its core responsibilities.

Furnace Inducer Motor at a Glance

Here is a quick summary of the key roles a furnace inducer motor plays every time your heat kicks on.

Function | Description |

|---|---|

Safety Pre-Purge | Clears out any residual, unburnt gases from the heat exchanger before ignition to prevent a dangerous buildup. |

Exhaust Venting | Actively pushes harmful combustion byproducts, including carbon monoxide, safely out of your home through the flue vent. |

Enabling Ignition | Creates the necessary pressure change that a safety device, the pressure switch, must detect before allowing the burners to light. |

Each of these functions is a critical link in the chain of operations that keeps your furnace running safely and effectively.

How the Inducer Motor Kicks Off the Heating Cycle

When you nudge the thermostat up on a cold day, you're setting off a carefully choreographed sequence inside your furnace. The very first component to spring into action is the inducer motor. Think of it as the opening act that has to get everything just right before the main event, the flame, can start.

Its immediate job isn't to create heat, but to create a safe environment for it. The motor spins up to generate a negative pressure, or draft, pulling air through the heat exchanger and pushing it out the exhaust vent. This is a critical safety check; the motor is essentially proving to the furnace that there’s a clear, unobstructed path for harmful combustion gases, like carbon monoxide, to safely exit your home.

This whole process is so vital that your furnace has a dedicated watchdog called the pressure switch. This small but mighty sensor is calibrated to detect the precise change in air pressure that only a properly running inducer motor can create.

The Critical Pre-Purge Cycle

Once the thermostat calls for heat and the inducer motor starts humming, it kicks off what we in the HVAC world call the "pre-purge" cycle. For about 30 to 60 seconds, the motor forcefully clears out any stale, leftover gases from the previous heating cycle that might be hanging around in the combustion chamber.

This step is all about preventing a dangerous situation known as "delayed ignition." Without this purge, a small pocket of unburnt gas could build up and ignite with a startling bang when the burners finally fire up. While this was more of a concern in older furnace models, modern systems have engineered this risk away. If you're dealing with an older furnace and its quirks, you might find our guide on what to do when a pilot light on a furnace keeps going out helpful.

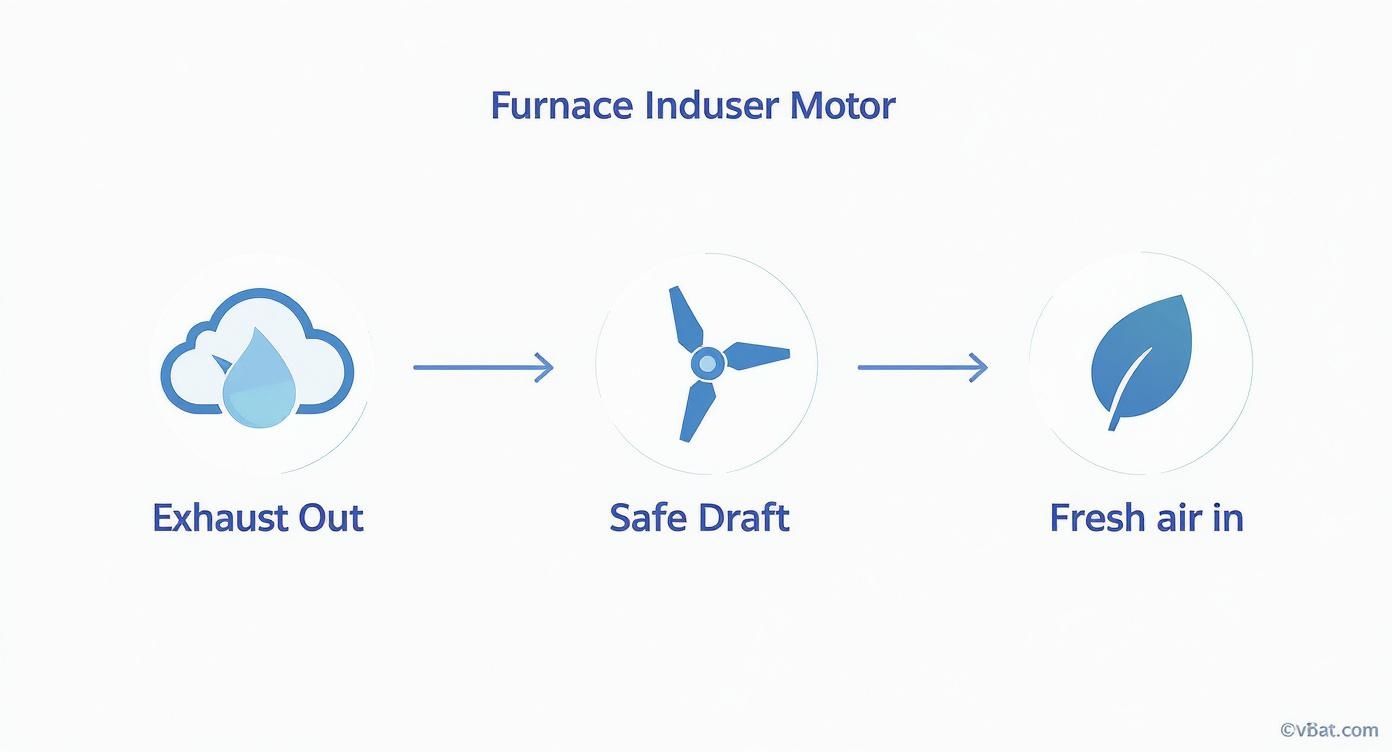

The infographic below breaks down the three core stages of the inducer motor's role in making combustion safe.

As you can see, the motor first pushes old exhaust out, then establishes a steady, safe draft, and finally clears the way for fresh air to be drawn in for a clean burn.

The Safety Handshake with the Pressure Switch

While the inducer motor is running, the pressure switch is essentially waiting for a secret handshake. The motor has to create the exact right amount of draft, and the switch has to "feel" it before anything else can happen.

If the pressure switch does not detect the correct negative pressure, it will not close its internal electrical circuit. This action directly prevents the furnace's main control board from opening the gas valve or activating the igniter.

This is your furnace’s most important safety interlock, hands down. It guarantees that under no circumstances can your furnace light a flame without a confirmed, safe escape route for the exhaust gases. This sequence makes it crystal clear why a failing inducer motor brings the entire heating system to a dead stop. No draft means no pressure change, no closed switch, and absolutely no heat.

Recognizing the Signs of a Failing Inducer Motor

A healthy furnace hums along quietly in the background, but a failing inducer motor is anything but subtle. It often announces its problems with very distinct, hard-to-miss sounds.

Since the inducer motor is the very first part to spring into action during the heating sequence, the best time to listen for trouble is right when your thermostat calls for heat. Catching these early warnings can be the difference between a simple repair and a full system breakdown on the coldest night of the year.

Strange noises are almost always the biggest red flag. You'll typically hear them just before the main blower fan kicks on, as the inducer motor struggles to create the right amount of draft.

Common Warning Sounds

The exact noise your furnace makes can give you some great clues about what's going wrong inside the inducer motor assembly. Think of it as your furnace's way of telling you where it hurts.

A High-Pitched Whining or Squealing: This is the classic sound of worn-out motor bearings. After years of spinning, the lubrication inside the bearings simply gives up, leading to metal-on-metal friction that creates a sharp, piercing noise.

A Loud Rattling or Scraping Noise: If it sounds like a small metal object is bouncing around inside, you're likely dealing with a problem with the fan blades. A blade could be bent, broken, or just off-balance, causing it to smack against the housing as it spins.

A Clicking or Ticking Sound: This often happens when the motor tries to start but can't quite get going. It could point to an electrical issue inside the motor itself or some kind of blockage that's physically preventing the fan from turning.

When a noise is consistent and shows up every single time the heat kicks on, it's a clear signal that the inducer motor needs a professional look, and soon.

Symptoms Beyond Strange Noises

While your ears are your best diagnostic tool, a failing inducer motor can cause other performance issues that are just as serious. These problems usually happen because the motor can no longer properly communicate with the furnace's safety sensors, especially the pressure switch.

A weak or dying motor might not spin fast enough to create the required draft. When that happens, the pressure switch won't close, and the furnace will refuse to ignite the burners as a safety measure. This failure can show up in a few different ways.

Important Insight: A furnace that starts its heating cycle but then shuts down before ever producing heat is a telltale sign of an inducer motor or pressure switch problem. The system is basically failing its initial safety check and aborting the mission.

Let's look at how a failing inducer motor can cause problems you'll feel or see, rather than just hear. The table below connects the dots between common symptoms and their likely causes.

Inducer Motor Failure Symptoms and Potential Causes

Symptom | What It Sounds/Looks Like | Potential Cause |

|---|---|---|

Furnace Starts and Stops | The inducer motor runs for a minute, then everything shuts down before the burners ignite. This is often called "short cycling." | The motor is too weak to create the necessary negative pressure, so the pressure switch correctly prevents ignition as a safety measure. |

No Heat at All | You hear a faint click from the thermostat, but nothing happens at the furnace. The inducer motor doesn't even try to start. | This could mean the motor has completely seized up or suffered an electrical failure, leaving it unable to respond to the call for heat. |

Error Codes on the Control Board | Modern furnaces have a control board with an LED light that flashes a specific sequence to signal a fault. | A very common code points directly to a "pressure switch stuck open" error, which is frequently the result of a malfunctioning inducer motor. |

These symptoms show that the problem goes beyond just an annoying noise. A failing inducer motor directly impacts your furnace's ability to safely and effectively heat your home.

If you're noticing your furnace is running but not really warming things up, it might not be a thermostat problem. For inconsistent heating, our guide on troubleshooting a furnace not blowing hot air offers quick tips that can help you narrow down the issue. More often than not, a failing inducer motor is the culprit behind a furnace that seems to be going through the motions without actually doing its job.

Of course. Here is the rewritten section, crafted to sound completely human-written and natural, following the provided style guide.

Common Causes of Inducer Motor Failure

So you've noticed the signs of a failing furnace inducer motor. That's the first step. The next is figuring out why it's failing. These motors are the unsung workhorses of your furnace, cycling on and off thousands of times every single heating season. All that starting and stopping puts a ton of stress on the components, and eventually, something has to give.

More often than not, the culprit behind a noisy or dead inducer motor is a simple case of worn-out motor bearings. These tiny parts are what allow the motor shaft to spin freely at incredibly high speeds. But with every cycle, they face intense heat and friction, and the lubrication they came with from the factory eventually breaks down. When that happens, you start hearing that classic high-pitched squeal or whine: the sound of metal grinding on metal, and a clear signal that a total failure isn't far behind.

Vibrations and Overheating Issues

Beyond the normal wear and tear on bearings, a few other things can really speed up the motor's demise. For instance, an unbalanced or damaged fan blade can introduce some seriously destructive vibrations into the whole assembly.

Even a tiny imbalance makes the motor work harder than it should, creating extra strain and noise. This constant shaking not only chews through the bearings faster but can also rattle electrical connections loose or even damage the motor's housing. This is often the source of those rattling or scraping sounds we talked about earlier.

Another big killer is motor overheating. The inducer motor is designed to have a steady stream of air moving over it to keep its cool. If that airflow gets choked off, usually by a severely clogged furnace filter, the motor can't get rid of heat effectively.

A dirty filter makes your entire HVAC system work harder, but the inducer motor is particularly vulnerable. The lack of proper airflow forces it to run hotter than designed, significantly shortening the lifespan of its internal electrical windings and bearings.

The Problem with Moisture

Finally, moisture and corrosion are the silent assassins of inducer motors, especially in modern high-efficiency furnaces. These systems are so good at pulling heat from the combustion process that the exhaust gases actually cool down enough to form condensation, a nasty, acidic liquid.

This condensation is supposed to be handled by a drainage system. But if a drain line gets clogged or the housing springs a leak, that acidic water can drip right onto the motor. This leads to rust and corrosion that can seize the bearings, eat away at the fan blades, and completely ruin the sensitive electrical parts. In these situations, the failure isn't from mechanical wear, but from a slow, corrosive attack from inside the furnace itself. Knowing these common causes really drives home why being proactive with maintenance is so critical to preventing a sudden, and expensive, breakdown.

How to Extend Your Inducer Motor's Lifespan

When it comes to your furnace, an ounce of prevention is truly worth a pound of cure. Taking a proactive approach to maintenance is the single best way to avoid a premature inducer motor failure and keep your heat running reliably all winter long. A few simple, consistent habits can make a world of difference.

Believe it or not, many of the best strategies involve caring for the entire furnace, not just the motor itself. For example, one of the most impactful things you can do is ensure the system has unrestricted airflow. When air moves freely, the motor doesn’t have to work as hard or run as hot, which dramatically reduces the strain on its bearings and electrical parts.

Simple Steps for Proactive Care

You don't need to be an HVAC pro to protect your furnace. A couple of straightforward tasks, done regularly, can add years to your inducer motor's life. These habits directly combat the most common culprits of failure, like overheating and blockages.

Change Your Furnace Filter Regularly: A clogged filter is public enemy number one for your entire HVAC system. A fresh, clean filter allows air to pass through easily, keeping the motor cool and preventing it from overworking just to do its job.

Keep Vents Clear of Obstructions: Your furnace’s intake and exhaust pipes must have a clear path to the outdoors. Make it a habit to check them for snow, leaves, animal nests, or anything else that could block the free flow of air.

A blocked vent forces the inducer motor to struggle against intense resistance, kind of like trying to breathe through a pinched straw. This constant strain leads to rapid overheating and burnout, making a clear vent path absolutely essential for longevity.

The Value of Professional Maintenance

While these DIY steps are critical, they don't take the place of an annual professional tune-up. An experienced technician has the tools and training to perform checks that go beyond basic upkeep. They can properly lubricate motor bearings where needed, inspect the fan wheel for balance and integrity, and make sure the condensate drain lines are clear to head off any moisture-related corrosion.

These routine inspections are designed to catch small issues before they snowball into catastrophic failures. To keep your system in top shape, it's always a good idea to schedule a professional gas furnace maintenance check with a certified technician. Think of it as a small investment that protects the hardworking components of your heating system, including that vital furnace inducer motor.

Navigating a Furnace Inducer Motor Replacement

When your furnace inducer motor gives up the ghost, the thought of getting it replaced can feel a bit overwhelming. But knowing what the process actually involves can take a lot of the stress out of the situation and help you make a clear-headed decision.

The first big question is whether to tackle it yourself or call in a professional.

While there's a certain satisfaction in a DIY home repair, replacing a furnace inducer motor is one of those jobs best left to the experts. This isn't like changing a lightbulb; you're dealing with your furnace's gas lines and high-voltage electrical components. One small mistake could lead to a dangerous gas leak, a nasty electrical shock, or, worst of all, improper venting of carbon monoxide. These are serious safety risks you just don't want to take with your family's well-being.

What to Expect From a Professional Service Call

When you get a certified HVAC technician on the line, they’ll follow a pretty standard playbook to get your heat running again safely. Knowing their steps can make the visit feel less like a mystery.

Initial Diagnosis: First things first, the tech will confirm the inducer motor is the actual culprit. They'll run tests on the motor, check the electrical connections, and inspect the pressure switch to make sure another part isn't causing the problem.

Part Sourcing: Once they've confirmed the diagnosis, they'll find the correct OEM (Original Equipment Manufacturer) or a compatible replacement motor for your specific furnace model.

Safe Replacement: This is the critical part. The technician will shut off both the gas and the electricity to the furnace before they even think about touching the old motor. Then, they'll carefully remove the old assembly and install the new one.

System Testing: After the new motor is in, they'll turn the power and gas back on. Then, they'll run your furnace through a full heating cycle to make sure the new motor is spinning up correctly and that the pressure switch is doing its job.

Key Insight: A professional replacement isn’t just about swapping out a broken part. It's about making sure the entire safety sequence of your furnace is back to factory standards, which is what truly protects your home and family.

Now, for the cost. It can vary quite a bit. The price tag depends on the motor itself (which changes by brand and model), the labor rates in your area, and how hard it is to get to your furnace. If your unit is tucked away in a cramped crawlspace, for example, the labor costs might be a bit higher.

While it’s an investment, a major repair like this sometimes brings up a bigger question: is it time to consider a full system upgrade instead? If your furnace is getting on in years, putting money into one part might just be a temporary fix. For more on that, you might want to look into the benefits of a full gas furnace replacement for your Arizona home.

Got Questions About Your Furnace Inducer Motor?

Even after getting the rundown on what a furnace inducer motor does, a few practical questions almost always pop up. Let's tackle some of the most common things homeowners ask about this critical part. Getting a handle on these will help you feel a lot more in control of your heating system.

Knowing the typical lifespan and the warning signs to listen for can be the difference between a simple repair and a full-blown, no-heat emergency.

How Long Does a Furnace Inducer Motor Typically Last?

A well-maintained furnace inducer motor should give you somewhere between 10 to 20 years of solid service. Of course, its actual lifespan depends on a few things, like how much your furnace runs, the quality of the original installation, and whether you're getting it professionally serviced. The motor bearings are usually the first part to start showing their age.

Staying on top of simple things, like changing your air filter, goes a long way. It cuts down on the strain and can definitely help nudge that motor’s lifespan closer to the 20-year mark.

Should I Run My Furnace if the Inducer Motor Is Noisy?

That's a hard no. A noisy inducer motor isn't just an annoyance; it's a clear signal that something is wrong and failure is likely on the horizon. The noise is typically caused by worn-out bearings or a fan that's gone off-balance. If you keep running the furnace, you risk the motor seizing up completely, leaving you in the cold when you least expect it.

But there's a more serious reason to shut it down. A failing motor might not be creating the right amount of draft to safely vent exhaust fumes. This could lead to a dangerous buildup of carbon monoxide in your home. Your best bet is to call a qualified HVAC technician to check it out right away and make sure your system is safe to operate.

The pressure switch is the unsung hero that works hand-in-hand with the inducer motor. Its entire job is to confirm that the motor is running correctly and pulling enough of a draft to clear out all the exhaust gases. If that switch doesn't sense the right pressure, it will refuse to let the furnace's gas valve open. No gas, no ignition, no danger.

This safety feature is precisely why a weak or dying inducer motor often trips a pressure switch error and shuts the whole system down before it can become a hazard.

If you're hearing strange noises or have any concerns about your furnace's performance, trust the experts at Covenant Aire Solutions. Our certified technicians can pinpoint any issue with your furnace inducer motor and get your system running safely and efficiently again. Visit us at covenantairesolutions.com to schedule your service call today.