What Refrigerant Replaces R22? A Complete Guide

- shawncovenantaire

- Aug 24, 2025

- 13 min read

Updated: Aug 25, 2025

So, you’re wondering what refrigerant replaces R-22? It’s a common question, and the answer isn't just about finding a new chemical; it's about understanding a major shift in the entire HVAC industry. The move away from R-22 was driven by global environmental regulations, pushing us toward modern hydrofluorocarbons (HFCs) like R-410A and R-407C.

The Story Behind the R-22 Refrigerant Phase-Out

For years, R-22 was the undisputed king of refrigerants. If you had an air conditioner installed before 2010, it almost certainly ran on R-22, often known by the brand name Freon. It was reliable and effective. But there was a hidden problem.

Scientists discovered that R-22 is a hydrochlorofluorocarbon (HCFC), a class of chemicals that wreaks havoc on the Earth’s ozone layer. When R-22 leaks into the atmosphere, the chlorine atom it contains acts like a tiny wrecking ball, breaking down the ozone molecules that protect us from harmful UV radiation. This was a serious environmental threat, and it kickstarted a worldwide effort to find a safer R-22 replacement.

The Global Push to Ban R-22

The phase-out wasn't just a recommendation; it was a global mandate. The Montreal Protocol, an international environmental treaty, was the driving force behind eliminating ozone-depleting substances like R-22. This agreement set a strict timeline for countries to slash their production and use of HCFCs, which you can read more about on sites like verifiedmarketreports.com.

The science is pretty clear when you look at the chemical's structure.

That single chlorine atom (Cl) is the entire reason R-22 was targeted. Its ability to destroy ozone molecules made finding an alternative a top priority for the HVAC world.

Key Milestones You Should Know

In the United States, the Environmental Protection Agency (EPA) managed the phase-out with a series of deadlines. These dates made R-22 increasingly scarce and, as a result, much more expensive.

Here are the critical dates that every property manager and homeowner needs to remember:

2010: The game changed. Manufacturers were banned from producing or importing new air conditioning systems that came pre-charged with R-22.

2020: The final nail in the coffin. The production and importation of R-22 were completely banned. The only R-22 available now is what has been recycled or reclaimed from old systems.

That 2020 ban is a huge deal. It means the supply of R-22 is finite and shrinking every day. This scarcity has caused the price of servicing an old R-22 system to skyrocket, making a full system replacement or a retrofit a much smarter financial move for the long haul.

A Quick Guide To R22 Replacement Options

If you're looking for what refrigerant replaces R-22, you'll quickly discover there's no single, universal "drop-in" solution. The right choice really boils down to your specific equipment, goals, and budget. Several modern alternatives have stepped up to fill the gap, each with its own set of properties and ideal applications.

The most common replacements you’ll hear about are R-410A and R-407C, which have become industry standards for very different reasons. R-410A is what you'll find in virtually all new air conditioning systems manufactured after 2010. On the other hand, R-407C is a popular choice for retrofitting older R-22 systems. Other options, like R-422D, also serve as solid retrofit refrigerants in certain scenarios.

Comparing Your R22 Alternatives

Getting a handle on the key differences between these options is the first step toward making a smart decision. The main things to weigh are their environmental impact, measured by Global Warming Potential (GWP) and Ozone Depletion Potential (ODP), and whether they're compatible with your existing hardware.

A critical point to remember is that R-410A operates at significantly higher pressures than R-22. This is non-negotiable. It absolutely cannot be used in an R-22 system; it requires equipment specifically designed for its intense operational demands.

To simplify things, here's a quick look at how the most common R-22 replacement options stack up for homeowners.

At-a-Glance Comparison of R22 Alternatives

Refrigerant | Common Use | Global Warming Potential (GWP) | Ozone Depletion Potential (ODP) | Retrofit or New System |

|---|---|---|---|---|

R-410A | New residential AC systems | 2,088 | 0 | Requires new system |

R-407C | Retrofitting existing R22 systems | 1,774 | 0 | Suitable for retrofits |

R-422D | Retrofitting commercial & residential AC | 2,729 | 0 | Suitable for retrofits |

This comparison makes it clear that while all modern alternatives have an ODP of zero (which is great news for the ozone layer), their GWP and system requirements are all over the map. For a more in-depth look at these choices, explore our complete guide for homeowners on R22 refrigerant replacement. Choosing correctly is all about balancing cost, efficiency, and the long-term viability of your system.

Comparing the Leading R22 Alternatives

Deciding what refrigerant to use in place of R-22 isn't just about looking at a spec sheet. While plenty of alternatives are out there, they are definitely not one-size-fits-all. You have to consider crucial factors like their operating pressures, overall efficiency, and the type of oil they need to run properly, all of which have a big impact on both cost and performance.

The two names you'll hear most often are R-410A and R-407C. They each have their place; R-410A is the go-to for brand-new systems, while R-407C is a workhorse for retrofitting older equipment. Knowing the real-world differences between them is the key to making a smart investment.

R-410A: The Modern Standard for New Systems

After 2010, R-410A (also known by brand names like Puron) quickly became the default refrigerant for residential air conditioners. It’s more efficient than R-22 and has an Ozone Depletion Potential (ODP) of zero, making it a much better choice for the ozone layer. However, how it operates is a completely different story.

The most critical thing to understand about R-410A is that it runs at pressures 50% to 60% higher than R-22. This means it is absolutely not a "drop-in" replacement. Trying to use R-410A in a system built for R-22 would cause a catastrophic failure of the compressor and other parts.

Because of this intense pressure difference, R-410A requires a full system replacement. The entire unit, compressor, coils, line sets, everything, has to be engineered specifically to handle that extra stress. It also uses a synthetic Polyolester (POE) oil, which won’t mix with the mineral oil found in old R-22 systems.

R-407C: The Go-To for Retrofits

For anyone not quite ready to shell out for a full system replacement, R-407C provides a practical way forward. This refrigerant was engineered to have thermodynamic properties very similar to R-22. This lets it work within the same pressure and temperature ranges, making it a favorite for retrofitting existing R-22 equipment.

Unlike R-410A, which is a near-azeotropic blend, R-407C is a zeotropic blend. This is a fancy way of saying its chemical components boil at slightly different temperatures. If a leak happens, the chemical makeup of the remaining refrigerant can get thrown off, which can hurt performance and mean you need a full recharge instead of a simple top-off.

Just like R-410A, it requires a switch from mineral oil to POE oil. This means a technician has to flush the entire system during the conversion to get all the old oil out and prevent contamination.

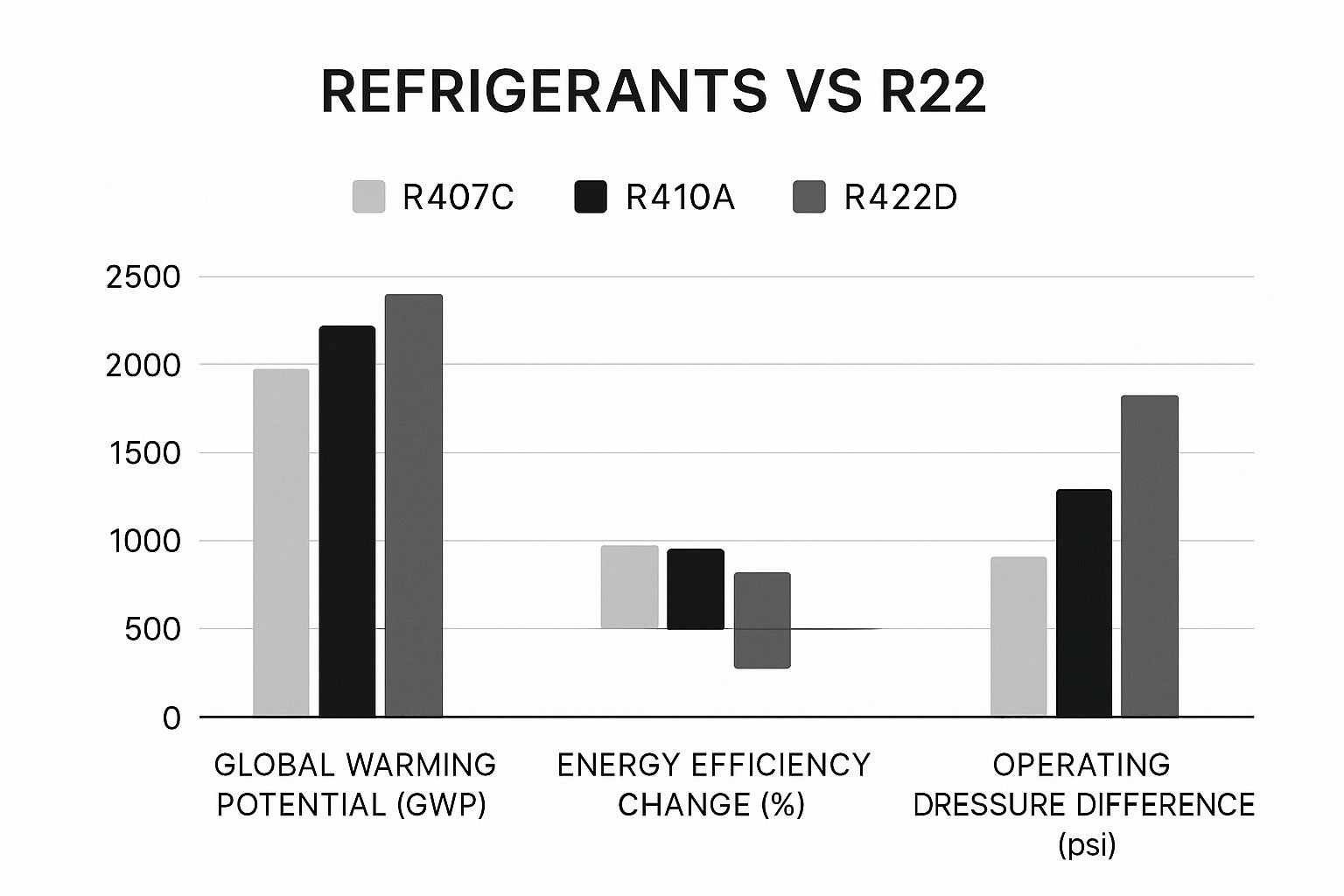

The chart below gives a great visual breakdown of how the leading R-22 alternatives stack up against the original.

You can clearly see the trade-offs here. Some replacements might have a lower Global Warming Potential (GWP), but they could operate at wildly different pressures.

Other Notable R-22 Retrofit Options

While R-407C is a solid choice for many retrofits, other refrigerants have been developed to be "drop-in" or "near drop-in" replacements to make the conversion process even simpler. One of the most common is R-422D, which you might also see sold as NU-22 or Freon MO29.

R-422D has a major advantage: it’s compatible with the traditional mineral oil and alkylbenzene (AB) lubricants used in R-22 systems. This often means you can skip the costly and time-consuming oil flush during a retrofit, which saves a bundle on labor and materials.

Here’s what you need to know about it:

No Oil Change Required: This is its biggest selling point and makes the conversion process much faster and cheaper.

Lower Capacity: Be aware that systems converted to R-422D usually lose a bit of cooling power, typically around 5-10%.

Higher GWP: Its Global Warming Potential is higher than both R-410A and R-407C, which is an important environmental factor to consider.

Picking the right alternative is all about balancing these factors. If you have an older system that’s nearing the end of its life anyway, a simple retrofit with R-422D could be a cost-effective way to keep it running. But for a healthier system with years of life left, the slightly more involved R-407C conversion might deliver better performance in the long run.

Choosing Your Strategy: Retrofit vs. Replace

Okay, so you know which refrigerants can replace R-22. That brings us to the big question: should you retrofit your current system, or is it time to replace it altogether?

There’s no single right answer here. The best path forward really depends on your specific situation; the age of your unit, your budget, and your long-term plans for the property are all part of the equation.

A retrofit is when a certified tech removes the R-22, flushes the lines, swaps out necessary parts like seals and lubricants, and then recharges it with a compatible replacement like R-407C. A replacement, on the other hand, means installing a brand-new, modern AC system designed from the ground up for today's refrigerants like R-410A.

When a Retrofit Makes Sense

Retrofitting can be a solid, cost-effective option if your R-22 system is still relatively young, say, less than 10 years old, and has a good track record with few repairs. If the unit is running efficiently and isn't giving you headaches, a retrofit can extend its life without the huge upfront cost of a new installation.

This strategy is often the best fit for someone who:

Has an HVAC system that’s still in excellent condition with no major component failures.

Is looking for a lower initial investment to get their system compliant and back to work.

Might be planning to move in the next few years and wants to avoid a major capital expense.

Here's something crucial to keep in mind: the supply of reclaimed R-22 is shrinking fast. Even if you wait, any future repair that needs a refrigerant top-off is going to get more and more expensive. A proactive retrofit is a smart financial hedge against that rising cost.

When a Full Replacement Is the Wiser Investment

If your R-22 system is over 10-15 years old, has a history of breaking down, or just can't seem to keep your space cool anymore, a full replacement is almost always the smarter move.

Yes, the initial cost is higher. But the long-term rewards in energy efficiency, reliability, and sheer peace of mind are substantial.

You should seriously consider a full replacement if:

Your system is old: An HVAC unit pushing the end of its typical 15-20 year lifespan is a ticking time bomb for an expensive, catastrophic failure.

You want better efficiency: Modern systems boast much higher SEER (Seasonal Energy Efficiency Ratio) ratings, which can slash your monthly electricity bills by up to 38%.

You plan to stay put: A new system is an investment that adds value to your property and ensures you won't have to worry about another major HVAC decision for well over a decade.

For anyone opting to replace, it helps to understand what the process looks like. Reading up on Replacing Outdated Refrigeration Units can give you some valuable context, especially if you have a more complex system. Ultimately, a new installation is an investment in reliability and efficiency.

If you decide to go this route, you’ll want the installation done right. Check out our guide at https://www.covenantairesolutions.com/post/your-ultimate-hvac-install-checklist-7-steps-for-2025 for a step-by-step checklist.

Steps in a Professional R22 Conversion

So, you’ve weighed the options and decided a retrofit is the right move for your R-22 system. Knowing what the process entails helps you ask the right questions and spot a job well done. An R-22 conversion is a highly technical procedure that must be handled by an EPA-certified technician. It’s a whole lot more involved than just draining the old stuff and pouring in the new.

One of the biggest mistakes anyone can make is trying to mix a replacement refrigerant with leftover R-22. This isn’t like topping off your oil. It can cause nasty chemical reactions, leading to poor cooling and, eventually, a catastrophic compressor failure. The entire system has to be methodically prepared to accept its new lifeblood.

The Core Conversion Process

A professional retrofit isn't a slap-dash job; it follows a precise set of steps designed to protect your equipment and ensure it runs reliably for years to come. While the exact details can shift depending on the replacement refrigerant, the fundamental process is always the same.

A certified technician will perform these key tasks:

Recover Existing R-22: First things first, all the old R-22 refrigerant has to be safely and completely recovered from the system using specialized equipment.

System Flush: The technician flushes the entire refrigerant circuit to get rid of the old mineral oil and any gunk or contaminants left behind. This is absolutely critical when switching to a refrigerant that requires Polyolester (POE) oil.

Component Replacement: Key seals and gaskets that might be incompatible with the new refrigerant or oil have to be replaced to prevent future leaks.

Vacuum and Leak Check: The system is then pulled into a deep vacuum to remove every last bit of moisture and non-condensable gases. A thorough leak check confirms the system is sealed up tight.

Charge with New Refrigerant: Finally, the system is carefully charged with the new refrigerant, like R-407C, according to the manufacturer’s specifications.

A common and disastrous shortcut is failing to properly flush out the old mineral oil. Mineral oil and the POE oil required by most replacements do not mix. Any leftover mineral oil will prevent proper lubrication, leading to premature compressor wear and eventual failure.

Ensuring System Health Post-Conversion

Once the new refrigerant is in, the job still isn't quite done. The system needs to be tested to make sure it’s operating within the correct pressure and temperature ranges for its new chemistry. A true professional will check the superheat and subcooling levels to fine-tune the charge, squeezing out every bit of performance and efficiency.

Proper maintenance becomes even more important after a retrofit. Scheduling regular tune-ups helps ensure the system continues to run smoothly. For some helpful pointers, check out our 2025 air conditioner tune-up checklist to keep your newly converted system in top shape. By understanding these steps, you can have a much more informed conversation with your HVAC provider and feel confident they’re taking every precaution to protect your investment.

What's Next for HVAC Refrigerants?

The world of cooling technology didn't just stop evolving after the first wave of R-22 replacements. In fact, the HVAC industry is already in the middle of another major shift, this time moving away from high-GWP refrigerants like R-410A. Getting a handle on this next wave is key to making a smart decision that keeps your system compliant and sustainable for years.

This whole movement is being pushed by regulations designed to slash greenhouse gas emissions. Because of that, the industry's focus is now on finding cooling agents with a much smaller environmental footprint. The conversation is shifting beyond HFCs and into more advanced, forward-thinking solutions.

The Next Generation of Refrigerants

The future really boils down to two main categories of coolants: Hydrofluoroolefins (HFOs) and natural refrigerants. These aren't just minor tweaks; they represent the next major step toward creating climate control that's both powerful and environmentally responsible.

HFOs: These are synthetic refrigerants, but with a twist. They break down in the atmosphere way faster than HFCs, which gives them a significantly lower GWP. A perfect example is R-454B, which is already set to become the new standard in residential systems manufactured after January 1, 2025.

Natural Refrigerants: This group includes substances like ammonia (R-717), carbon dioxide (R-744), and propane (R-290). They're incredibly efficient and have a GWP that’s practically zero. However, their flammability or toxicity means they're usually limited to specific commercial or industrial jobs where safety can be tightly controlled.

This evolution isn't just happening in home AC units. It's affecting all sorts of equipment, including commercial refrigerators, where staying efficient and compliant is just as critical. This industry-wide transition is part of a bigger commitment to sustainable tech. For homeowners, it means that even the newest R-410A systems on the market today will eventually be phased out for these better alternatives.

The Critical Role of Reclamation and Recycling

As the industry pushes forward, we still have to deal with the massive existing stock of older refrigerants. That's where reclamation and recycling become so important. Instead of just venting harmful chemicals into the atmosphere (which is illegal and irresponsible), certified technicians are trained to recover old refrigerants from systems being retired.

Reclamation is the process of taking used refrigerant and cleaning it up to meet the same purity standards as a brand-new product. This allows the limited supply of gases like R-22 to be reused for servicing older equipment, extending the life of systems that aren't quite ready for a full replacement.

This kind of responsible management is a cornerstone of the modern HVAC world. The phase-out of R-22 has also spurred incredible innovation in developing and adopting these alternative refrigerants. Here in North America, the focus has really shifted to HFOs and natural refrigerants because of their superior environmental performance. The industry is backing this transition by investing in reclamation and recycling tech, allowing technicians to keep existing R-22 systems running while guiding customers toward more sustainable solutions.

When you're choosing a new system or a retrofit strategy, keeping this future in mind is crucial. It ensures your investment is not just efficient today, but also aligned with the regulations of tomorrow. For more ideas on getting the most out of your system, check out our guide on pro HVAC energy-saving tips for Arizona homes.

Common Questions We Hear About R22 Replacements

When you're figuring out what to do with an older R22 system, a lot of questions come up. We get it. Here are some clear, straightforward answers to the things homeowners and property managers ask us most.

Can I Just Top Off My R22 System with a New Refrigerant?

No, you absolutely cannot. Under no circumstances should you ever mix R22 with a replacement refrigerant. Think of it like putting diesel in a gasoline engine, it's a recipe for disaster. The chemical mismatch can cause poor performance, dangerous pressure spikes, and ultimately, catastrophic compressor failure. It'll also instantly void any warranty you might have.

A proper conversion is a meticulous job. A certified technician has to recover every last drop of the old R22, flush the entire system to get rid of old oil and contaminants, and often replace critical parts like seals before charging it with the new alternative.

The most important thing to remember is that refrigerants are not interchangeable. Each one has unique chemical properties and pressure characteristics. Mixing them creates an unstable and dangerous cocktail inside your HVAC system.

Is R410A the Best Replacement for R22?

This is a common point of confusion. While R-410A became the industry standard for new residential air conditioners after the R22 phase-out, it is not a "drop-in" or retrofit replacement for an R22 system. It operates at much higher pressures and demands equipment specifically built to handle that stress. Trying to force it into an R22 unit is both impossible and unsafe.

For older systems where you aren't replacing the whole unit, a retrofit-friendly option like R-407C is a much more practical choice. These alternatives are engineered to mimic R22’s operating characteristics, which makes them compatible with existing hardware once a proper conversion is done.

How Do I Know if My System Uses R22 Refrigerant?

Finding out what refrigerant your system uses is usually pretty simple. Just head outside and look for a data plate or sticker on your outdoor condenser unit. This label should clearly state the type of refrigerant the system was designed for. You'll likely see it listed as "R-22" or "HCFC-22."

If you can't find the label or it's been worn down and is unreadable, please don't guess. A licensed HVAC technician can identify it for you in minutes. Regular check-ups are key to system health anyway, and you can learn more about what that involves by reviewing an **HVAC preventative maintenance checklist**.

If you still have questions or need professional guidance on your R22 system, the certified experts at Covenant Aire Solutions are here to help. We provide honest advice and expert service to ensure your home stays comfortable and compliant. Visit us at https://www.covenantairesolutions.com to schedule a consultation.