What Is a Scroll Compressor an HVAC Explainer

- Nov 14, 2025

- 15 min read

If you've ever wondered what makes your modern air conditioner or heat pump hum along so quietly and efficiently, the answer is likely a scroll compressor. Think of it as the heart of your HVAC system, tirelessly pumping refrigerant to keep your home comfortable.

Let's take a quick look at what makes this component so special before we dive deeper.

Scroll Compressor At a Glance

Characteristic | Description |

|---|---|

Operation | Uses two intertwined spirals to continuously compress refrigerant gas. |

Efficiency | Highly efficient due to its continuous motion and fewer moving parts. |

Noise Level | Very quiet operation with minimal vibration. |

Reliability | Excellent durability and a long operational lifespan. |

Applications | Dominates residential and light commercial HVAC systems. |

This table gives you the highlights, but the real magic is in how it all works together.

The Quiet Heart of Your HVAC System

Tucked away inside your outdoor unit is a marvel of engineering that directly impacts your comfort and energy bills. Unlike older piston-style compressors that clunk and vibrate with a start-stop motion, the scroll compressor works with a smooth, continuous flow.

Imagine two spirals, one nested inside the other. One spiral remains perfectly still while the other orbits around it. This elegant movement creates pockets of refrigerant gas that get smaller and smaller, compressing the gas as they move toward the center. It’s this fluid motion that makes these units so famously quiet.

Because the design is so simple, with far fewer moving parts than its predecessors, there's less that can go wrong. That translates directly into better durability and a longer life for your system.

From Old Idea to Modern Marvel

Believe it or not, the concept for the scroll compressor isn't new. It was actually invented way back in 1905 by a Frenchman named Léon Creux. He patented the design, but the manufacturing technology of his time just couldn't create the perfectly matched spirals needed for it to work.

It took until the 1980s, when precision computer-controlled machining became available, for the scroll compressor to finally become a commercial reality. It quickly became the go-to choice for residential and light commercial HVAC systems, and it's easy to see why.

A key takeaway is that the scroll compressor's design inherently provides higher volumetric efficiency compared to traditional reciprocating compressors. This means it moves more refrigerant with each rotation, directly contributing to lower energy consumption.

Where the Compressor Fits In

To really grasp what a scroll compressor is, you need to see its role in the bigger picture. It's just one part of a team of components that includes the condenser, evaporator, and more.

To see how everything connects and works in harmony, check out our complete homeowner's guide to the parts of a central air conditioner. Understanding its place in the system really highlights just how essential its job is.

How a Scroll Compressor Actually Works

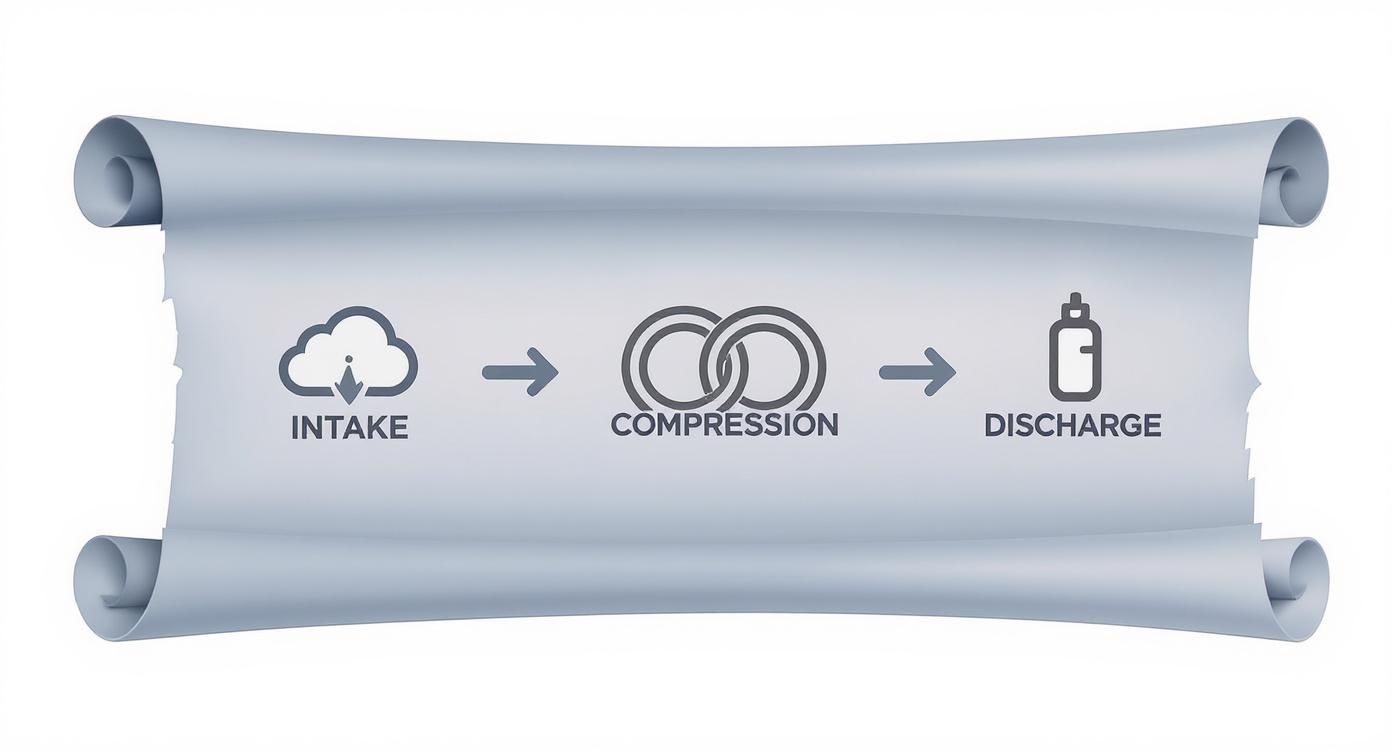

To really get what a scroll compressor is, you have to picture what’s happening inside. It’s a beautifully simple, continuous cycle that boils down to three stages: intake, compression, and discharge. Forget the technical diagrams for a second and think of it like tightly rolling up a sleeping bag to squeeze all the air out. That's the basic idea.

This whole process relies on two perfectly matched spiral pieces, or scrolls. One is the stationary scroll, and as its name implies, it doesn’t move. The other, the orbiting scroll, moves in a tight circle around the stationary one without actually spinning on its axis. This elegant orbital dance is the secret behind its smooth, quiet power.

The Intake Stage: Sucking In Refrigerant

The action starts at the outer edges of these spirals. As the orbiting scroll moves, it creates crescent-shaped gaps that open up at the perimeter, acting like an intake port. This opening pulls in low-pressure, cool refrigerant gas that’s just come from your system's evaporator coil.

This isn't a start-stop process. With every single orbit, the scroll is constantly gulping in more refrigerant gas, trapping it in little pockets between the two spiral walls. Unlike an old-school piston compressor that takes in air in distinct, separate gulps, the scroll compressor's intake is a seamless, uninterrupted flow.

The Compression Stage: The Squeeze

Once that refrigerant gas is trapped in those outer pockets, the real work begins. The orbiting scroll keeps moving, which seals off the pockets of gas and gradually forces them toward the center of the spirals. As these pockets travel inward, they get progressively smaller and smaller.

This shrinking volume is where the magic happens. Basic physics tells us that when you squeeze a gas into a smaller space, its pressure and temperature shoot up. The scroll compressor does this with incredible smoothness, steadily raising the refrigerant's pressure without the jarring pulses you’d get from older designs.

What’s really efficient is that multiple pockets of refrigerant are being compressed at the same time, all at different points along the spiral path. This continuous, multi-stage compression is what makes the technology so effective. There are no wasted motions, just a constant, powerful squeeze.

The Discharge Stage: Releasing High-Pressure Gas

Finally, when the pockets of refrigerant reach the dead center of the scroll set, they've been squeezed down to their maximum pressure. A discharge port is waiting right at this central point. The now high-pressure, high-temperature refrigerant gas bursts out through this port.

From here, the superheated gas is on its way to the next major component in your AC system. To see where it goes next and how it gets rid of all that heat, check out our guide that explains what a condenser unit is and what it does in the cooling cycle.

This final stage is just as smooth as the first two. Because new pockets are always arriving at the center, the output is a steady stream of pressurized gas, not the pulsating bursts that come from a reciprocating compressor. This even flow reduces strain on the rest of your HVAC system and is a big reason why these units run so quietly.

Let's quickly recap what happens in each stage:

Intake: Low-pressure refrigerant gas is constantly drawn into the outer edges of the scrolls.

Compression: The orbiting motion seals the gas into pockets and pushes them toward the center, shrinking their volume to increase pressure and temperature.

Discharge: Highly pressurized gas is released from a port at the very center in a constant, smooth flow.

This three-stage cycle repeats thousands of times a minute, giving your air conditioner the consistent flow of refrigerant it needs to cool your home. The beauty of the scroll compressor lies in its mechanical simplicity and fluid motion, which deliver superior efficiency and enhanced reliability with far fewer moving parts than other compressor types.

The Real-World Benefits of Scroll Technology

There's a reason manufacturers and seasoned HVAC technicians alike are big fans of scroll compressors. It's not just about technical specs on a manual; their unique design translates into real, tangible advantages you can see, hear, and feel right in your home. These benefits directly impact your monthly energy bills, your day-to-day comfort, and how long your HVAC system will last.

This clever engineering boils down to four key perks: incredible energy efficiency, whisper-quiet operation, enhanced durability, and a surprisingly compact size. Each of these is a direct result of the compressor's simple, continuous motion. Let's break down how this smarter design creates a better home environment.

Superior Energy Efficiency

The number one reason to get excited about a scroll compressor is its remarkable energy efficiency. Older piston-style compressors waste energy opening and closing valves. Scroll compressors, on the other hand, don't have these energy-sucking parts. Their constant orbital motion means no "re-expansion loss," which is a fancy term for when trapped high-pressure gas expands back into the cylinder, wasting power.

Simply put, more of the electricity your HVAC system uses goes directly toward compressing refrigerant and actually cooling your home. Over the life of your system, that higher efficiency can add up to some serious savings on your utility bills. Understanding your system's performance is key, and you can learn more by checking out our guide to HVAC system efficiency.

This infographic gives you a great visual of the simple, three-step dance of intake, compression, and discharge that makes this technology so effective.

As you can see, the process is a smooth, uninterrupted flow. That's the secret sauce behind its efficiency and quiet operation.

Near-Silent Operation

If you’ve ever lived with an older air conditioner, you know the routine: that loud, jarring clank and shudder when the compressor kicks on. A scroll compressor pretty much eliminates that racket. Its smooth, continuous orbiting motion produces so little vibration and sound that you often won't even notice it's running.

This quiet performance is thanks to two main design features:

Continuous Motion: There’s no abrupt starting and stopping like you get with a piston, which is where most of the noise comes from.

Fewer Moving Parts: With just two main components doing the work (the scrolls), there are far fewer parts to rattle, vibrate, and make a fuss.

The result is a much more peaceful home, both inside and out. You can actually enjoy a conversation in your backyard without a roaring AC unit interrupting, and you won't be woken up by the system cycling on and off all night.

Enhanced Durability and Reliability

It's a simple rule of engineering: the simpler the design, the more reliable the machine. A scroll compressor has far fewer moving parts compared to an old-school reciprocating compressor, which can have dozens of components like pistons, rings, valves, and rods. Fewer parts mean fewer things that can break.

This streamlined design also makes scroll compressors tougher. They can handle minor system issues like liquid refrigerant "slugging" that would completely destroy other types of compressors. This built-in durability means a longer lifespan for your system and fewer emergency calls for costly repairs, giving you some well-deserved peace of mind.

Compact and Lightweight Design

Finally, the efficient design of a scroll compressor allows it to be much smaller and lighter than the bulky, old-fashioned compressors that deliver the same cooling power. This smaller footprint gives HVAC manufacturers more freedom when designing the outdoor units. For you, the homeowner, that can mean a less obtrusive unit that takes up less of your valuable yard space.

This compact nature is just one more reason the technology became so popular. After manufacturing breakthroughs made them affordable in the 1980s, scroll compressors quickly found their way into over 50% of new residential air conditioners in major markets. That trend was driven by their unbeatable mix of efficiency, quiet operation, and rock-solid reliability.

Comparing Compressor Types for Your HVAC System

To really get why scroll compressors became the gold standard in home HVAC, it helps to line one up against the alternatives. The world of HVAC compressors really boils down to three main designs: scroll, reciprocating, and rotary. Each has a different mechanical game plan for compressing refrigerant, and those differences ripple out to affect everything from your energy bills to how loud your backyard is on a summer afternoon.

Think of it like choosing an engine for a car. A loud, rumbling V8 might be perfect for a muscle car, but you wouldn't want that racket in a quiet family sedan. In the same way, a clunky, vibrating reciprocating compressor might be fine in an industrial plant, but the quiet, smooth efficiency of a scroll compressor is a much better fit for a residential home.

The Three Main Contenders

Before we pit them against each other, let’s quickly meet the players. We’ve already covered the smooth, orbital motion of the scroll compressor. Its main rivals work very differently.

Reciprocating Compressor: This is the old-school workhorse of the industry. It functions much like a car engine's piston, using an up-and-down motion inside a cylinder to pull in and squeeze refrigerant gas. While it’s powerful, all that starting and stopping creates a lot of noise and vibration.

Rotary Compressor: This type uses a small roller spinning inside a cylinder to trap and compress refrigerant. It’s more compact and generally quieter than a reciprocating model, which is why you’ll often find them in smaller units like window ACs and dehumidifiers.

So, how do these three technologies really compare when it comes to the things that matter most to a homeowner: efficiency, noise, reliability, and where they’re best used?

Scroll vs Reciprocating vs Rotary Compressor Showdown

The clearest way to see the pros and cons of each compressor is to put them side-by-side. This table breaks down their most important characteristics to show where each one shines (and where it falls short).

Feature | Scroll Compressor | Reciprocating Compressor | Rotary Compressor |

|---|---|---|---|

Efficiency | Very high; continuous compression with minimal energy loss. | Lower; energy is lost in the stop-start motion and through valves. | Moderate; more efficient than reciprocating but less than scroll. |

Noise Level | Very low; smooth, continuous motion creates minimal sound and vibration. | High; the piston's motion causes significant noise and vibration. | Low to moderate; quieter than reciprocating but noisier than scroll. |

Reliability | Excellent; has very few moving parts, leading to a long lifespan. | Good; a proven but complex design with many parts that can wear out. | Good; simple design but can be susceptible to wear over time. |

Applications | Residential & light commercial AC, heat pumps, refrigeration. | Large commercial systems, industrial refrigeration, older residential units. | Window AC units, dehumidifiers, smaller ductless systems. |

As the table makes clear, the scroll compressor is the consistent winner for home use, where quiet operation and high efficiency are king. Its design, with only one primary moving part (the orbiting scroll), is its killer feature, giving it superior reliability and lower maintenance needs over its lifetime.

The core takeaway is that while each compressor type has its place, the scroll's balanced profile of efficiency, quietness, and durability makes it the clear winner for modern home comfort systems.

Why the Right Choice Matters for Modern Systems

The type of compressor in your outdoor unit does more than just affect noise levels; it's the heart of your system's performance. This is especially true with today's more advanced HVAC technology. For instance, high-efficiency systems often use variable-speed technology to precisely match your home's heating and cooling demands, saving a huge amount on energy bills.

Scroll compressors are a perfect match for this job. Their design plays incredibly well with variable-speed motors, allowing them to ramp their output up or down smoothly and efficiently. This synergy is a key reason you can learn how variable-speed heat pumps maximize comfort and savings in our detailed guide. A reciprocating compressor, with its rigid, piston-driven cycle, just can't offer that same level of fine-tuned control.

Ultimately, knowing the difference helps you understand why that quiet, gentle hum from a modern AC unit, the sound of a scroll compressor at work, has become the sound of efficient, comfortable living.

Where Do You Find Scroll Compressors? Common Applications

Once you get a handle on how these compressors work and the benefits they bring to the table, it’s easy to see why they’ve become so popular. This isn't just theory; scroll technology powers countless devices we rely on every single day. Its versatility makes it the engine behind everything from home comfort systems to critical industrial equipment.

The most common place you'll find a scroll compressor is inside residential air conditioners and heat pumps. For homeowners, the combination of quiet operation, high efficiency, and rock-solid reliability is the perfect recipe for a comfortable and peaceful home.

Commercial HVAC and Refrigeration

Scroll compressors are also the workhorses of the commercial world. Look up at the roof of most office buildings, retail stores, and restaurants, and you’ll find them humming away inside HVAC units. Their durability and efficiency are absolutely essential for managing the climate in these bigger spaces.

Their reach extends deep into commercial refrigeration, too. The next time you’re walking through a supermarket, know that scroll compressors are likely what's keeping the produce crisp and the dairy aisle perfectly chilled. They deliver the consistent cooling needed for:

Display Cases: Keeping food at safe temperatures while it’s out for customers.

Walk-In Coolers: Making sure large stocks of perishable goods stay fresh.

Food Processing Facilities: Holding the precise temperatures required for food safety and quality.

For businesses that install and maintain these large-scale systems, managing cash flow is key. Understanding options like dedicated financing for HVAC contractors can be a game-changer for planning jobs and growing the company.

The widespread adoption in both homes and businesses makes one thing clear: scroll technology has become the go-to standard for any application that needs consistent, dependable, and efficient performance without a lot of noise.

Specialized and High-Tech Industries

Beyond everyday heating and cooling, the adaptable design of the scroll compressor has pushed it into some highly specialized fields. Its clean, pulsation-free output is vital in environments where precision and purity are non-negotiable.

Over the last couple of decades, huge strides in technology have opened the door for scroll compressors in advanced applications, including oil-free and high-pressure systems. For example, pioneering designs have led to liquid-cooled, oil-free scroll compressors being used in high-performance portable oxygen concentrators and even aerospace water systems.

By 2007, some of these oil-free scroll designs were hitting pressures over 14 bar gauge, a massive leap beyond what was thought possible, showing off their incredible engineering potential.

This expansion into such demanding sectors really proves how robust and flexible scroll compressors are. Their continuous evolution ensures they'll remain a vital part of a growing list of critical technologies all over the world.

Spotting Trouble: Common Scroll Compressor Issues

Even though scroll compressors are built like tanks, they aren't invincible. Knowing what to look and listen for is the best defense a homeowner has against a surprise breakdown. Catching the early warning signs can stop a small hiccup from turning into a catastrophic and expensive failure.

Many problems give off clear signals, like the unit refusing to start, making bizarre noises, or cycling on and off constantly. The goal here isn't to turn you into an HVAC pro overnight, but to help you recognize when something's wrong so you can explain it clearly to a technician. That knowledge alone can speed up a repair and save you money.

Common Symptoms and What They Mean

When a scroll compressor starts to fail, it usually doesn't do so quietly. It sends out distress signals, some loud and obvious, others more subtle. Here are the most frequent signs of trouble:

Failure to Start: You hear the thermostat click, but the outdoor unit just sits there, silent. Or maybe it just hums quietly. This almost always points to an electrical problem, like a failed capacitor or a wiring issue.

Weird Noises: Scroll compressors are known for being quiet, but they aren't totally silent. If you suddenly hear a loud grinding, screeching, or rattling sound, that’s a major red flag. It often means there’s a serious internal mechanical failure, like busted bearings or broken scroll tips.

Constant Cycling: Your AC or heat pump kicks on, runs for a few minutes, then shuts off, over and over again. This is called short cycling, and it can be triggered by anything from a clogged air filter choking the airflow to low refrigerant levels.

If a rattling sound is what you're hearing, it's worth digging a bit deeper into what could be causing it. Check out our detailed guide on why your air conditioning unit is rattling to learn more.

Electrical vs. Mechanical Faults

It helps to think about compressor problems in two main buckets: electrical and mechanical. Electrical issues are usually simpler and cheaper to fix. Mechanical failures, on the other hand, are the ones that get serious fast.

Electrical Issues are, by far, the more common culprit. A frequent point of failure is the capacitor, a small component that gives the compressor motor the electrical "kick" it needs to get started. Other electrical gremlins include bad wiring, a burnt-out contactor, or problems inside the motor's windings.

A tell-tale sign of a bad capacitor is a distinct humming sound coming from the compressor, but the fan isn't spinning. For a qualified technician, this is a pretty straightforward fix.

Mechanical Failures involve the actual moving parts inside the compressor. We're talking about things like worn-out bearings that cause those awful grinding noises or failed internal seals that lead to a complete loss of compression. Because scroll compressors are hermetically sealed units, you can't just open them up and replace a broken part. These kinds of internal failures almost always mean the entire compressor needs to be replaced.

Frequently Asked Questions About Scroll Compressors

Alright, we've covered a lot about what a scroll compressor is and how it works. To tie it all together, let's tackle some of the most common questions homeowners have. These quick answers should clear up any last-minute thoughts you have about this super-efficient technology.

How Long Does a Scroll Compressor Typically Last?

A well-maintained scroll compressor is a real workhorse. In a typical home HVAC system, you can expect it to last anywhere from 10 to 20 years. This impressive lifespan comes from its elegantly simple design; it just has far fewer moving parts to wear out compared to older compressor styles.

Of course, several things can affect how long it lives. The quality of the initial installation is huge, as is keeping up with professional maintenance like cleaning coils and checking refrigerant levels. Your local climate also plays a role. Sticking to the manufacturer's recommended service schedule is the single best thing you can do to get the most years out of it.

Can a Scroll Compressor Be Repaired?

This is a great question and one we get a lot. Scroll compressors are what we call hermetically sealed units. This means they’re welded completely shut at the factory. Because of this design, it's pretty much impossible for a technician in the field to open one up and fix an internal part, like a damaged scroll or a bad motor winding.

So, in almost every case of an internal mechanical failure, the entire compressor unit gets replaced, not repaired. But here's the important part: many problems that seem like a dead compressor are actually external. Things like a bad capacitor, a faulty relay, or wiring issues are common and can be easily fixed by a qualified HVAC technician without touching the compressor itself.

It's a common misconception that any compressor problem means you need a whole new unit. A thorough diagnosis from a pro is essential to tell the difference between a simple electrical issue and a true internal failure.

Are Scroll Compressors More Expensive?

Looking at the sticker price, an HVAC system with a scroll compressor might have a slightly higher upfront cost than one with a traditional reciprocating compressor. But that initial price tag doesn't tell the whole story. You have to look at the total cost of ownership.

That higher purchase price is often balanced out by some serious long-term savings. Here’s how:

Energy Efficiency: Their smart design means they use less electricity, which directly lowers your monthly utility bills.

Durability: They are incredibly reliable and built tough, which means fewer service calls and lower repair costs over the years.

When you add up the energy savings and reduced maintenance, a scroll compressor often turns out to be the more economical choice in the long run, giving you both better comfort and financial benefits.

When your HVAC system needs an expert eye, you need a team you can trust for honest diagnostics and reliable solutions. For any issues with your scroll compressor or other heating and cooling needs, contact Covenant Aire Solutions for prompt, professional service. You can learn more about our commitment to your comfort on our website.