A Homeowner Guide to Parts of an Air Conditioner Condenser

- 13 hours ago

- 16 min read

That big metal box humming away outside your Tucson home does more than just make noise, it’s the engine room for your entire cooling system. The air conditioner condenser has one primary job: to take all the heat absorbed from inside your home and dump it into the blistering Arizona air. Think of it as your house's radiator, working tirelessly to make sure cool, comfortable air is all that's left inside.

This whole process relies on a few key parts working in perfect harmony. Every component, from the powerhouse compressor to the simple fan blades, plays a vital role. Knowing how these pieces fit together is a game-changer for any homeowner, especially in a climate where a reliable AC isn't a luxury, it's a lifeline.

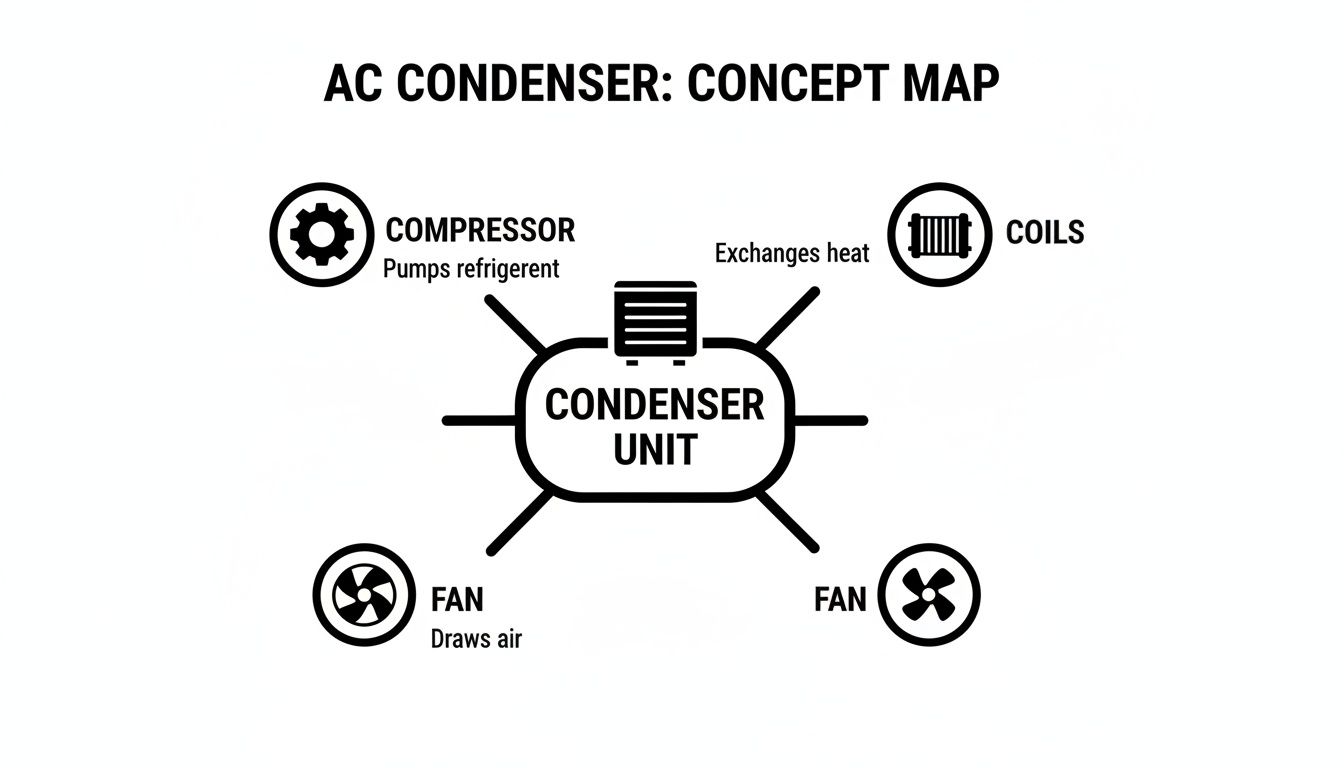

This map breaks down how the three main parts of an air conditioner condenser work together: the compressor, the coils, and the fan.

As you can see, the condenser unit is the central hub where these three critical components interact to get the heat out. If you're curious about the science behind it all, this is a great resource on how an aircon works.

Why This Matters for Tucson Homeowners

Spotting the signs of trouble early can save you from a complete breakdown during a brutal summer heatwave and keep you from spending a fortune on major repairs. When you understand the basics of your condenser, you can describe problems more clearly to a technician (like us!) and make smarter decisions about maintenance.

This guide will walk you through the most important parts of an air conditioner condenser, explaining what they do in plain English. We’ll cover:

The Compressor: The heart of the system that gets the refrigerant moving.

The Condenser Coils: The maze of tubing where heat actually escapes.

The Fan: The part that blows the heat away and speeds up the cooling process.

Electrical Parts: The contactor and capacitors that give the unit its power.

A well-maintained condenser doesn't just keep you cool; it runs more efficiently, which can slash your energy bills by 5% to 15%. Regular checks and cleanings prevent the kind of strain that leads to an early system failure.

To give you a quick overview, here's a simple table summarizing the main components.

Quick Guide to Key AC Condenser Components

Component | Primary Function | Common Problem Sign |

|---|---|---|

Compressor | Pressurizes and pumps refrigerant through the system. | Loud buzzing or clanking noises. |

Condenser Coil | Releases trapped heat from the refrigerant into the air. | Ice buildup or reduced cooling. |

Condenser Fan | Pulls air over the coils to help dissipate heat. | The fan blades aren't spinning. |

Capacitor | Provides the electrical jolt to start the motors. | The unit hums but won't start. |

Contactor | A switch that sends power to the unit. | The outdoor unit won't turn on at all. |

This table is just a starting point. By the end of this guide, you'll have a clear picture of how your outdoor unit functions and why each part is so important. For more foundational info, check out our post on what a condenser unit is and the role it plays in your home's comfort.

The Compressor: The Heart of Your Cooling System

If we think of the outdoor condenser unit as the engine room for your home's cooling system, then the compressor is unquestionably its heart. It's the single most critical, powerful, and, frankly, most expensive component packed into that metal box in your yard. Its job is simple in theory but absolutely vital in practice: to pump refrigerant through the entire system, just like your heart circulates blood.

Without a healthy compressor, your AC is just a glorified fan.

This powerhouse of a pump draws in low-pressure, cool refrigerant gas from the indoor unit and, like its name says, compresses it. This process drastically increases the refrigerant's pressure, which in turn skyrockets its temperature. A great real-world example is pumping up a bicycle tire, you can feel the pump getting warm as the pressure inside builds. This superheated, high-pressure gas is now ready to shed all that heat into the Tucson air, which is the whole point of the condenser unit.

Types of AC Compressors

Now, not all compressors are built the same. The specific type inside your unit has a big impact on its efficiency, how loud it is, and its overall performance. For most homeowners in Tucson, you'll run into one of two main types: reciprocating and scroll compressors.

Reciprocating Compressors: These are the old workhorses. They function a lot like the pistons in a car's engine, using an up-and-down motion to squeeze the refrigerant gas. It's a proven technology, but they tend to be much louder and less energy-efficient than their modern counterparts.

Scroll Compressors: This newer design uses two intricately nested spirals, one that stays still and another that orbits around it, to compress the refrigerant. Because there are fewer moving parts, they are a whole lot quieter, more reliable, and significantly more energy-efficient. It's no surprise that most new residential AC units today are built with a scroll compressor.

That efficiency gap isn't just a minor detail. Upgrading to a system with a modern scroll compressor can make a real difference you can see on your monthly TEP bill. If you're curious about this superior technology, check out our guide on what a scroll compressor is and how it works.

Common Warning Signs of Compressor Failure

Because the compressor works so hard, it's susceptible to wear and tear over the years, especially under the strain of our intense Arizona heat. A failing compressor isn't a minor hiccup; it's a serious problem that demands immediate professional attention. If you ignore the warning signs, you're looking at a complete system breakdown, which always seems to happen on the hottest day of the year.

A failing compressor is one of the most significant AC repairs a homeowner can face. Recognizing the early symptoms is the best way to prevent a costly and inconvenient system failure. Don't wait for the problem to escalate.

Keep an eye (and an ear) out for these red flags that could mean your compressor is on its last legs:

Strange and Loud Noises: Your AC unit will always make some noise, but a compressor in distress often makes very distinct sounds. Listen for any loud buzzing, clanking, or rattling that you haven't heard before. These sounds often mean internal mechanical parts have come loose or are failing.

Weak or Warm Airflow: If the air trickling out of your vents feels lukewarm or the airflow just isn't what it used to be, the compressor might not be pressurizing the refrigerant properly. It's a classic sign that the heart of your system isn't pumping with enough force.

Frequent Circuit Breaker Trips: The compressor needs a huge jolt of power to get started. If it's starting to fail, it can draw too much current and trip your home's circuit breaker over and over. This is a serious electrical hazard and a major red flag.

Outdoor Unit Shakes Violently on Startup: A compressor that's struggling to kick on can cause the entire outdoor unit to shake or shudder violently. We call this a "hard start," and it puts a massive amount of strain on every component in the system.

If you notice any of these symptoms, the smartest and safest thing to do is turn off your air conditioner immediately and call a certified technician at Covenant Aire Solutions. Trying to diagnose or fix a compressor yourself is incredibly dangerous due to the high voltages and pressurized refrigerant involved. Our team has the tools and expertise to accurately diagnose your compressor's health and recommend the best path forward, whether that's a repair or a full replacement.

How Condenser Coils and Fans Release Trapped Heat

So, the compressor has done its job, squeezing the refrigerant into a superheated gas. Now the system has to get rid of all that heat it pulled from your house. This is where two of the most visible parts of your outdoor unit come into play: the condenser coils and the big fan on top. Think of them as your home's heat exhaust system, working together to vent all that unwanted warmth into the Tucson air.

If you peek through the grates of your condenser, you'll see a massive network of copper tubing snaking back and forth. These are the condenser coils. Much like the radiator in your car, their main purpose is to create a huge surface area for the hot refrigerant to travel through, giving the heat an easy escape route. To make this process even more efficient, the coils are covered with thousands of paper-thin aluminum fins. These fins act like tiny heat sinks, dramatically expanding the surface area and supercharging the heat transfer process.

Hovering right above the coils is the powerful condenser fan. This is the workhorse that pulls massive amounts of our hot Tucson air through those fins and across the coils. As it does, it whisks away the heat radiating from the refrigerant, blasting it out the top of the unit. This constant, powerful airflow is what cools the refrigerant gas enough to turn it back into a liquid, ready to head back inside and absorb even more heat from your home.

The Enemy of Efficiency: Dirty Coils

Because that fan is constantly pulling in outside air, it’s also sucking in dust, leaves, pollen, and all that cottonwood fluff we see every spring. Over time, this gunk builds up on the condenser coils, forming a thick, insulating blanket. This is, hands down, the most common maintenance problem we see, and it can absolutely cripple your AC's performance.

When the coils are caked in dirt, they simply can't release heat the way they're supposed to. The refrigerant inside stays too hot, forcing the compressor to run much harder and longer just to cool your home. This extra strain leads directly to some pretty serious problems.

Skyrocketing Energy Bills: A system fighting against dirty coils can use 15% to 30% more electricity to get the job done. That’s a difference you’ll definitely feel on your TEP bill.

Reduced Cooling Performance: Your AC will struggle to keep up on those 100-degree days, running nonstop without ever quite hitting the temperature you set on the thermostat.

Increased Wear and Tear: The added stress puts immense pressure on the compressor and fan motor, which can shorten their lifespan and lead to premature, and expensive, breakdowns.

If neglect goes on for too long and leads to irreversible corrosion, you could be looking at the significant cost to replace a condenser coil.

Did you know? The condenser coil has been a core component of air conditioning since Willis Carrier invented the first modern system back in 1902. He designed it to control humidity at a printing plant in Brooklyn, using coils filled with cold water to cool the air. It's a testament to how fundamental this heat exchange process is.

Keeping Your Coils and Fan in Top Shape

Keeping your condenser coils and fan clean is one of the single most effective things you can do to keep your AC running efficiently all summer. While some jobs are best left to the pros, there are a few simple things every homeowner can do.

First, give your unit some breathing room. Make sure you keep bushes, weeds, and any overhanging branches trimmed back, leaving at least two feet of clearance on all sides. This ensures it can pull in enough air. Second, you can give the coils a gentle rinse with a garden hose yourself.

For a truly deep and safe cleaning, though, it's best to call in a professional. We've put together a handy guide on how to clean condenser coils for more details. But if your coils are heavily caked with grime, give the experts at Covenant Aire Solutions a call. We have the specialized tools and cleaning agents to restore your coils to like-new condition without bending those delicate aluminum fins, making sure your system is ready to beat the Tucson heat.

The Electrical Components That Power Your AC

While the compressor, coils, and fan are the mechanical muscle, the electrical parts are the brains and nervous system of your condenser unit. These components work behind the scenes, managing the flow of high-voltage power to make sure everything kicks on at the right time and runs without a hitch. Without them, your AC is just a silent metal box sitting outside.

Think of your thermostat as the general giving an order; the electrical components are the officers who execute that command. They take the low-voltage signal from inside your home and translate it into the powerful action needed to start the compressor and fan motor. This all happens in a split second, every single time your home needs cooling.

The Contactor: The Heavy-Duty Switch

The first key player in this electrical chain of command is the contactor. In simple terms, it’s a heavy-duty electrical switch. When your thermostat calls for cool air, it energizes a small electromagnet inside the contactor. This pulls a metal plunger down, closing a high-voltage circuit.

That action is like flipping a massive light switch. It instantly sends the powerful 240 volts needed to run the compressor and the condenser fan motor. Once your home reaches the right temperature, the thermostat cuts the signal, the electromagnet releases, and the circuit opens, shutting the unit down.

Since it's a mechanical switch that opens and closes thousands of times each season, it can eventually wear out. Pitting on the contact points from electrical arcing, or even insects crawling inside, can cause it to fail.

Capacitors: The Power Boosters

Next up are the capacitors, which are essential for getting the motors moving in the first place. Think of a capacitor as a small, temporary battery. It stores an electrical charge and then releases it in a powerful burst to give the compressor and fan motors the jolt they need to start spinning.

You’ll typically find two types of capacitors in your condenser unit:

Start Capacitor: This one provides the powerful, initial kick needed to get the compressor turning from a dead stop.

Run Capacitor: Once the motor is up and running, this capacitor supplies a smaller, steady stream of energy to keep it spinning efficiently and smoothly.

A failing capacitor is one of the most common reasons we get service calls here in Tucson. The intense summer heat is especially hard on them, causing them to degrade and fail over time.

A tell-tale sign of a bad capacitor is when your outdoor unit hums but the fan or compressor won't actually start. The motor is trying to engage but doesn't have the electrical boost it needs to get going, which creates that distinct humming or buzzing sound.

Recognizing Electrical Problems

Spotting the signs of electrical failure is critical, as these issues can quickly damage more expensive parts like the compressor. You don't need to be an electrician to notice something is off, but you do need to know when it's time to call a professional. If you're interested in the technical side, you can learn more by exploring how to read HVAC wiring diagrams in our guide.

Here are the most common symptoms of electrical trouble:

Symptom | Potential Electrical Cause |

|---|---|

Unit hums but won't start | The capacitor has likely failed and can't provide the jolt to start the motor. |

Outdoor fan won't spin | This could be a bad fan motor, but it's often a failed run capacitor for the fan. |

Condenser won't turn on at all | The contactor might be stuck open or has failed, preventing power from reaching the unit. |

AC trips the circuit breaker | A failing capacitor or a short in the wiring can cause a power surge that trips the breaker. |

CRITICAL SAFETY WARNING: The electrical components in your AC condenser operate on high voltage, which is extremely dangerous. Never attempt to diagnose or replace a contactor or capacitor yourself. Always shut off power at the breaker and call a certified technician from Covenant Aire Solutions for safe and reliable electrical repairs.

The Unsung Heroes: Valves, Lines, and Driers

Beyond the big-ticket items like the compressor and fan, there's a whole network of smaller parts that are absolutely essential for keeping your refrigerant flowing and pure. These are the unsung heroes of your outdoor unit, the valves, lines, and driers that manage the health of your system's lifeblood.

Frankly, even a brand-new, top-of-the-line compressor would burn itself out in no time without this crucial supporting cast. Small issues here, like a tiny leak or a clogged filter, can quickly snowball into major cooling problems and some seriously expensive damage. Knowing what they do gives you a better appreciation for just how complex your AC system really is.

Service Valves and Refrigerant Lines

Take a look at your outdoor unit, and you'll spot two copper pipes connecting it back to your house. These are the refrigerant lines, and they act just like a circulatory system, moving refrigerant between the indoor and outdoor components. Right near those connections, you'll find the service valves, which are critical access ports for technicians.

Think of these valves like the ports a doctor uses to check your blood pressure. Our technicians at Covenant Aire Solutions hook their gauges right up to these valves to measure the system's pressures and see how much refrigerant is in there. It’s the only safe and accurate way to get a true diagnosis of what’s happening inside the refrigerant circuit.

A properly charged air conditioner is a sealed system. That means it should never lose refrigerant. If a tech tells you you're low, it's a dead giveaway that there's a leak somewhere in the lines or coils that needs to be found and fixed.

The Filter Drier: Your System's Kidney

Tucked away in the refrigerant lines is a small but mighty component called the filter drier. The best way to think of it is as your AC system's kidney. Its entire job is to filter out any moisture and debris that might have snuck into the sealed refrigerant circuit, usually during the initial installation or a past repair.

Moisture is the absolute worst enemy of an AC system. When water mixes with refrigerant, it can form nasty corrosive acids that literally eat away at the compressor's internal parts, leading to a total system meltdown. The filter drier is there to trap that moisture, along with any tiny metal shavings or dirt, keeping the refrigerant clean.

Because it's constantly trapping gunk, a filter drier can eventually get clogged up. Here are a few tell-tale signs:

Your AC just isn't cooling like it used to, because the clog is slowing down refrigerant flow.

You spot ice or frost building up on the copper lines or even on your indoor coil.

A technician will notice unusually high pressure readings on one side of the system.

A clogged filter drier forces the compressor to work way harder than it should, putting a massive strain on the most expensive part of your system. This is exactly why technicians will almost always replace the filter drier anytime they have to open up the refrigerant system for a major repair.

The type of refrigerant in your system also plays a big part in its maintenance needs. To learn more, check out our guide on what replaces older refrigerants like R-22 and see why keeping it pure is so critical.

When It's Time to Call in the Pros at Covenant Aire Solutions

Now that you've got a handle on the key parts of an air conditioner condenser, from the workhorse compressor to the tiny electrical capacitors, you're in a much better position to spot trouble before it ruins a hot summer day. You can see how the coils and fan team up to push heat out of your home, how the contactor acts like a light switch for your whole system, and why the filter drier is the unsung hero protecting everything. Each piece has a job, and together, they keep your Tucson home livable.

This knowledge is powerful. It helps you do the simple things, like making sure bushes aren't crowding the unit or giving the coils a gentle rinse with a hose. But let's be clear: the mix of high-voltage parts and high-pressure refrigerant lines makes most AC work a dangerous game for a DIYer. Getting a proper diagnosis and a safe fix takes special tools and years of certified training.

When To Call The Experts at Covenant Aire Solutions

While a little TLC from you goes a long way, professional service is what really ensures the long, efficient life of your air conditioner. The guts of an AC condenser are unforgiving. One small mistake can snowball into a much bigger, more expensive headache, or worse, a serious injury. A certified tech can safely spot problems that are totally invisible to the untrained eye.

You should always pick up the phone and call a pro for things like this:

Electrical Issues: Hear a humming or buzzing sound but the unit won't kick on? That's a classic sign of a bad capacitor or contactor, both of which hold a dangerous electrical charge.

Refrigerant Problems: If your AC is blowing warm air or you spot ice forming on the copper lines, you've likely got a refrigerant leak. Only EPA-certified technicians are legally allowed to handle refrigerant.

Loud Mechanical Noises: Any clanking, grinding, or screeching sounds are a red flag. This could mean serious internal damage to the compressor or fan motor that needs an expert's attention right away.

Your Trusted HVAC Partner in Tucson

Here at Covenant Aire Solutions, we're not just a repair service, we aim to be your partner in total home comfort. Our certified technicians have the expertise to service every single one of the parts of an air conditioner condenser, making sure your system is ready to perform when you need it most. We've built our reputation on honest, transparent service, without ever trying to upsell you on things you don't need.

We're big believers in proactive care. Our preventative maintenance plans are specifically designed to catch small issues before they become catastrophic failures, saving you the stress and cost of an emergency breakdown during a Tucson heatwave.

Don't wait for a minor hiccup to turn into a full-blown crisis. Let our team make sure your air conditioner is primed and ready to take on the intense summer heat. And with our 24/7 emergency availability, you can relax knowing we're always here to help. Contact Covenant Aire Solutions today to schedule your tune-up and protect your investment.

Common Questions We Hear About AC Condensers

Tucson homeowners are smart, and they ask great questions about their AC systems. Getting straight answers is the best way to understand how your unit works and know for sure when it's time to call in a pro. Here are a few of the most common questions we get here at Covenant Aire Solutions.

How Often Should I Clean My Condenser Unit?

Here in our dusty desert environment, we strongly recommend a professional cleaning at least once a year, usually as part of a regular maintenance plan. In between those visits, you can definitely help things along. Just be sure to shut off the power at the breaker first, then gently rinse the exterior fins with a garden hose every couple of months. Never, ever use a pressure washer, it will bend those delicate aluminum fins in a heartbeat.

This simple bit of upkeep clears away the loose dust, leaves, and grime that build up, allowing your unit to breathe. That directly boosts its efficiency and takes a lot of strain off crucial parts like the compressor and fan motor, especially during our brutal summer months.

What's That Loud Buzzing Noise Coming From My Condenser?

A loud, steady buzzing or humming sound is almost always a red flag for an electrical problem inside the unit. The most frequent culprits are a failing contactor or a bad capacitor. These components are what kickstart the motors, and when they go bad, the motors try to turn on but can't get the electrical juice they need.

This isn't just an annoying noise; it's a critical warning sign. Because these electrical parts operate on dangerous high voltage, you should never try to fix this yourself. If you hear that buzzing, turn off your AC at the thermostat and then at the circuit breaker. Then, call a certified technician right away to prevent more serious damage.

Should I Repair or Replace a Failing AC Compressor?

That’s the million-dollar question, and honestly, the right answer depends on a few things. A compressor replacement is one of the biggest and most expensive AC repairs you can face. When we help homeowners make this call, we look at a few key points together:

Age of the System: If your AC is pushing 10-12 years old or more, sinking a huge amount of money into a new compressor might not be the wisest move. It's often more practical to put that repair money toward a brand-new, high-efficiency system.

Warranty Status: The first thing to check is whether your compressor is still under the manufacturer's warranty. A valid warranty can slash the repair cost dramatically.

Refrigerant Type: Older systems often use R-22 refrigerant, which is now phased out and incredibly expensive to source. In that case, upgrading to a modern system that uses a current refrigerant is usually the smarter financial decision.

A certified technician can give you an honest, no-nonsense assessment, laying out the costs and benefits of both repair and replacement. That way, you have all the information you need to make the right choice for your home and budget.

If you're dealing with any of these issues or just have more questions about your AC condenser, don't sweat it. Covenant Aire Solutions is here to provide honest diagnostics and reliable repairs to keep your Tucson-area home cool and comfortable. Contact us today to schedule service.